Other Parts Discussed in Thread: BOOSTXL-TUSS4470, TUSS4470, TDC1011,

Hello,

I'm trying to use the TDC1000 in a fluid (liquid) identification scenario. I'm still in the early stages of development where I'm trying to make sure I'm configuring and controlling the TDC1000 properly and checking for transducer signals on my oscilloscope. The transducer I'm using is the one recommended by TI for liquid applications (www.steminc.com/.../piezoceramic-disc-10x2mm-r-215-khz-wireleads-smd10t2r111wl). I'm controlling the TDC1000 with a PIC16F18446 operating at 16MHz and outputting a clock signal to the TDC1000 at 8MHz.

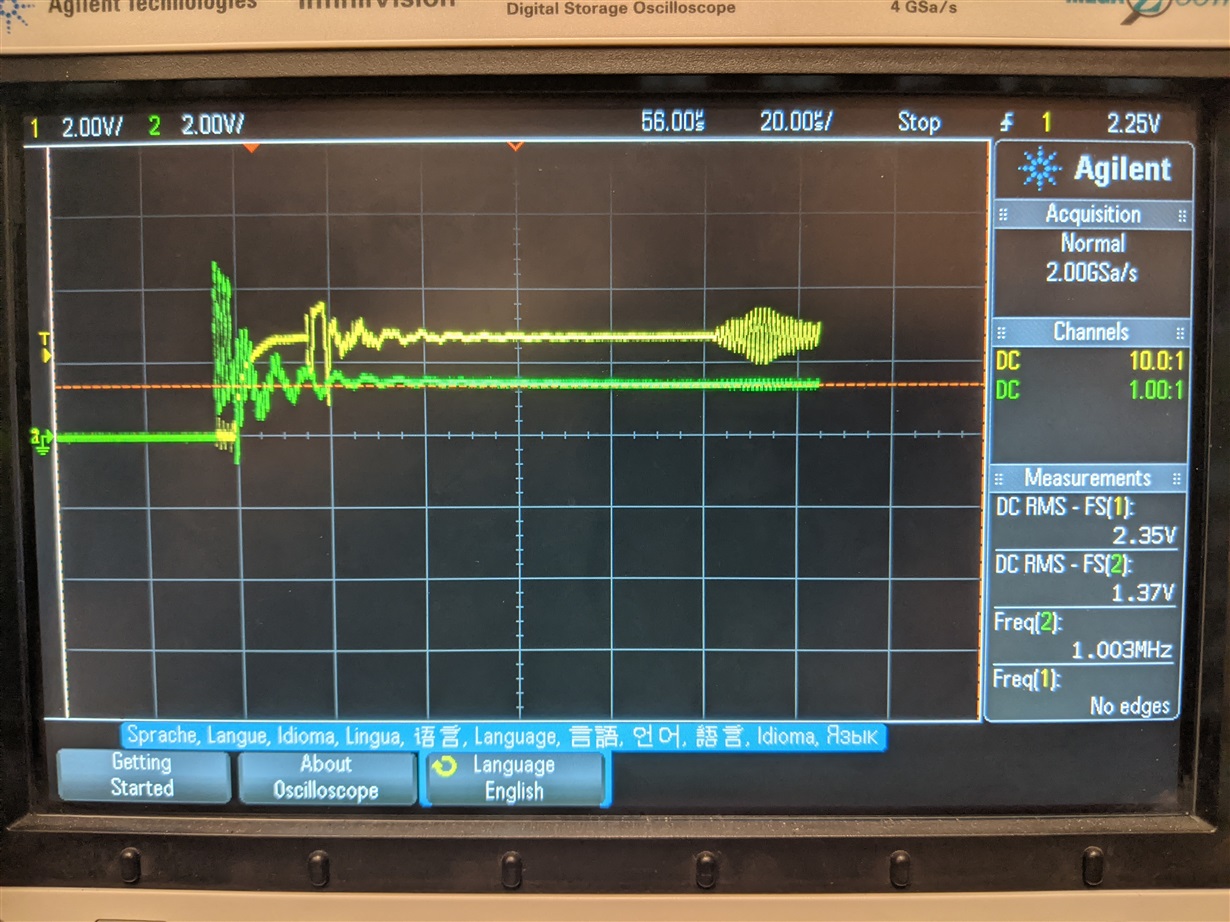

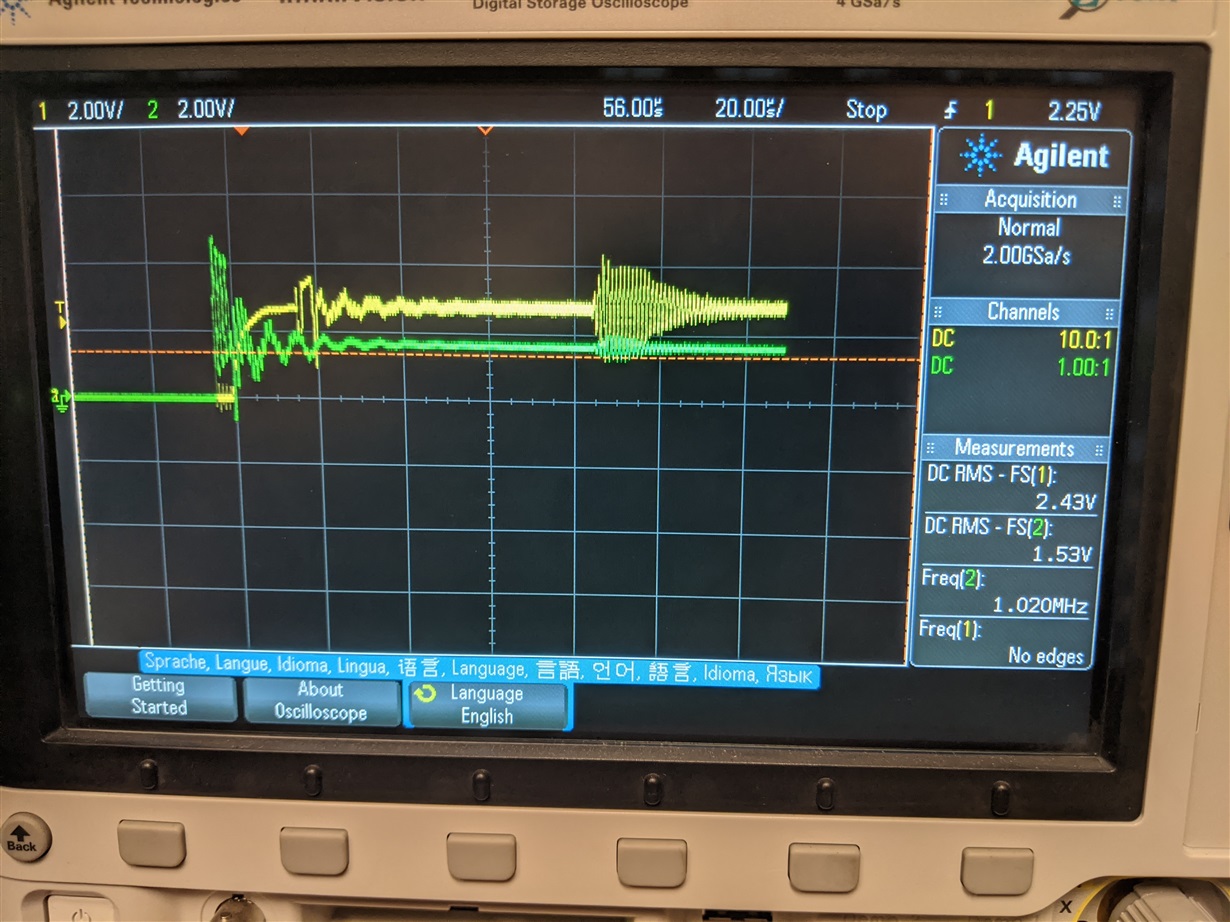

So the problem I'm having is that the time between the TRIGGER signal generated by the PIC and the START pulse generated by the TDC1000 is almost one order of magnitude higher than what the datasheet says. See the photo below.

All the registers are configured in their default state, except the Config_0 register which is set as 0x44. I only changed that one as a first step to make sure I can properly configure the TDC1000 through the PIC.

Can anyone help with why that could be happening?

It might not sound like a big deal but I'm also not getting an echo signal back, so I'm wondering if these problems are related in any way. I'm trying to tackle one issue at a time. :)

Any help will be much appreciated.

Thank you,

Theodore