Other Parts Discussed in Thread: LDC1612, LDC1614, LDC1314

I am currently trying to measure the self-inductance of a coil using LDC1614EVM for a research project in which we use Arduino to control the entire system.

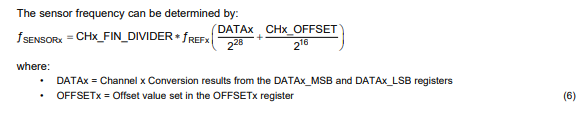

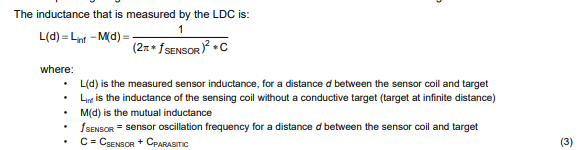

I found an LDC1612/1614 driver library for Arduino and tried it as is. Although it worked, it does not seem to be returning the inductance value. The self-inductance of this coil is around 2[µH] but the numbers I receive are around 149*10^6.

I’m assuming this output value is the frequency that LDC1614 receives from the coil.

The code I’m using is below. Could you possibly have a look at this code and figure out how to translate the output value into inductance? Or if you could provide me other libraries that potentially work the way I want, that would be greatly appreciated too.

For your reference, this library is from here.

/**

******************************************************************************

* File Name : LDC1614_example

* Description : Example program for LDC16xx_lib

******************************************************************************

*

* Copyright (c) 2018 CNR-STIIMA DASM Group

* All rights reserved.

*

* Redistribution and use in source and binary forms, with or without modification,

* are permitted provided that the following conditions are met:

*

* 1. Redistributions of source code must retain the above copyright notice,

* this list of conditions and the following disclaimer.

* 2. Redistributions in binary form must reproduce the above copyright notice,

* this list of conditions and the following disclaimer in the documentation

* and/or other materials provided with the distribution.

* 3. The name of the author may not be used to endorse or promote products

* derived from this software without specific prior written permission.

*

* THIS SOFTWARE IS PROVIDED BY THE AUTHOR ``AS IS'' AND ANY EXPRESS OR IMPLIED

* WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

* MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT

* SHALL THE AUTHOR BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

* EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT

* OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS

* INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN

* CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING

* IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY

* OF SUCH DAMAGE.

*

* Credits go to Jeremi Wójcicki (and the current maintainers) of this software.

*

**/

#include "LDC16xx_lib.h"

// user selecatable comppile option

// 0 - use user polling to read sensor data

// 1 - use syncronized sensor read with INTB pin interrupt

#define IRQ_HANDLER 0

// single channel conversion setup with disabled INTB by default

LDC_configReg default_config[] = {

{ LDC16xx_MUX_CONFIG, LDC16xx_BITS_DEGLITCH_3_3Mhz },

{ LDC16xx_CONFIG, LDC16xx_BITS_ACTIVE_CHAN_CH0 | LDC16xx_BITS_AUTO_AMP_DIS | LDC16xx_BITS_INTB_DIS },

{ LDC16xx_SETTLECOUNT_CH0, 0x0050 },

{ LDC16xx_RCOUNT_CH0, 0xffff },

};

#define LDC_CONFIG_SIZE sizeof(default_config)/sizeof(LDC_configReg)

// global sensor object pointer

LDC16xx *ldc;

// an ISR control flag for pending sensor data

volatile bool drdy = 0;

// interrupt service routine - when sensor conversion is complete

// this code should be light not to block the main loop for too long

void onDataReady(){

drdy = true;

}

void setup() {

// put your setup code here, to run once:

Serial.begin(115200);

Serial.println("Starting execution ...");

// create a new LDC sensor object, initialize interface

// I2C clock of 100kHz or 400kHz is allowed

ldc = new LDC16xx(Wire, 400000);

// verify chip ID. On fail halt program

uint16_t id, manuf;

ldc->readRegister(LDC16xx_DEVICE_ID, &id);

ldc->readRegister(LDC16xx_MANUFACTURER_ID, &manuf);

Serial.print("Chip ID: 0x");

Serial.println(id, HEX);

Serial.print("Manufacturer ID: 0x");

Serial.println(manuf,HEX);

if(id == LCD16xx_DEFAULT_DEVICE_ID && manuf == LDC16xx_DEFAULT_MANUFACTURER_ID){

Serial.println("Verification OK");

} else {

Serial.println("Wrong chip or manufacturer ID, stopping execution...");

while(1);

}

// reset device wiping previous configuration

ldc->resetDevice();

// load our config

ldc->loadConfig(default_config, LDC_CONFIG_SIZE);

#if IRQ_HANDLER == 1

// attach IRQ and set appropriate LDC registers to enable INTB interrupt

// depending on used board consult www.arduino.cc/.../ for possible pin configurations

// user pin 2 for INTB

ldc->enableDataReadyInterrupt(2, onDataReady);

#endif

// for debug, dump values of all register to the console

ldc->registerDump(Serial);

}

// main loop

void loop() {

#if IRQ_HANDLER == 1

while(!drdy);

drdy = false;

#endif

uint32_t data;

uint16_t status;

// read the channel no 0. data

ldc->readChannel(0, &data);

#if IRQ_HANDLER == 1

// in IRQ mode status must be read to re-enable conversion and re-assert INTB

ldc->readRegister(LDC16xx_STATUS, &status);

#endif

// print read data in the console

Serial.println(data, DEC);

#if IRQ_HANDLER == 0

// we time the loop by ourselves (optionally we could ask the chip periodically for status)

// ideally you should make sure we are syncronized with sensor conversion rate (RCOUNT + clock source)

delay(24); // ~41.5 sps

#endif

}