Other Parts Discussed in Thread: UNIFLASH, AWR1642,

Tool/software: Code Composer Studio

Help!

i am using the AWR1642BOOST development board and i seem to have hit an issue with temperature instability.

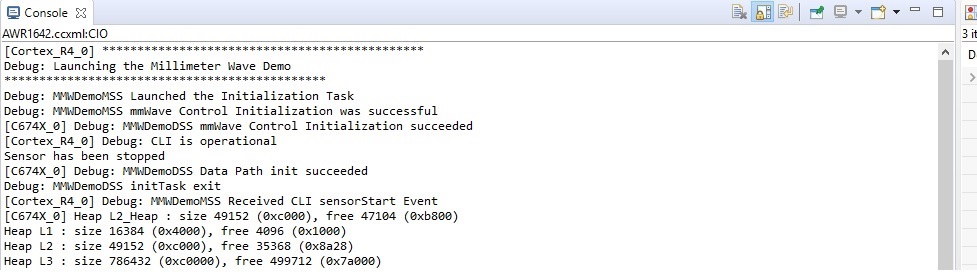

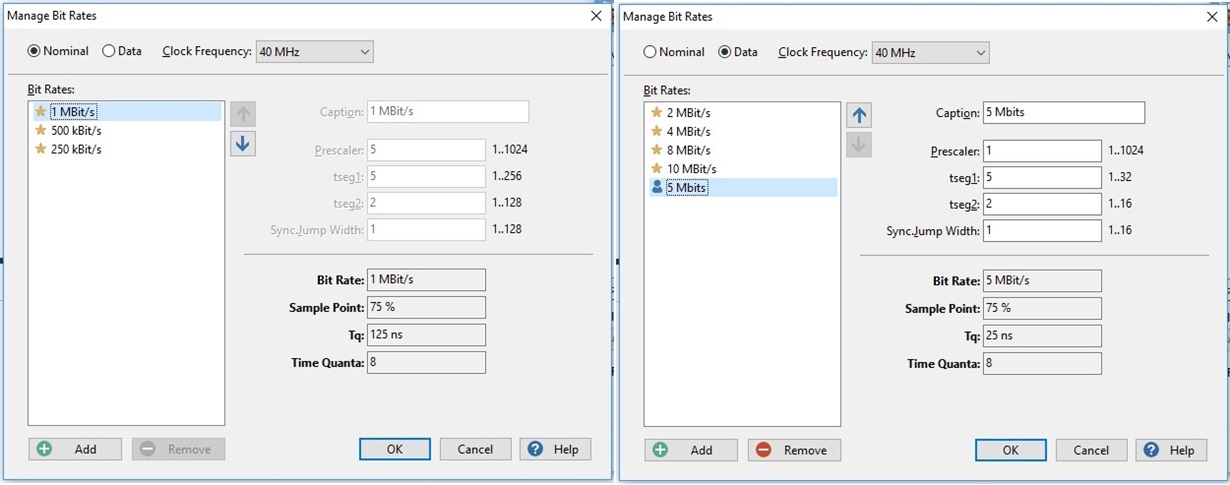

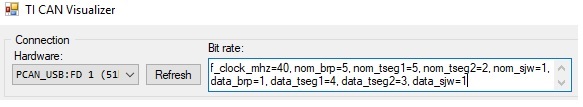

i have programmed the board with the radar data over CAN software and have a working compiling software set in Code Composer studio.

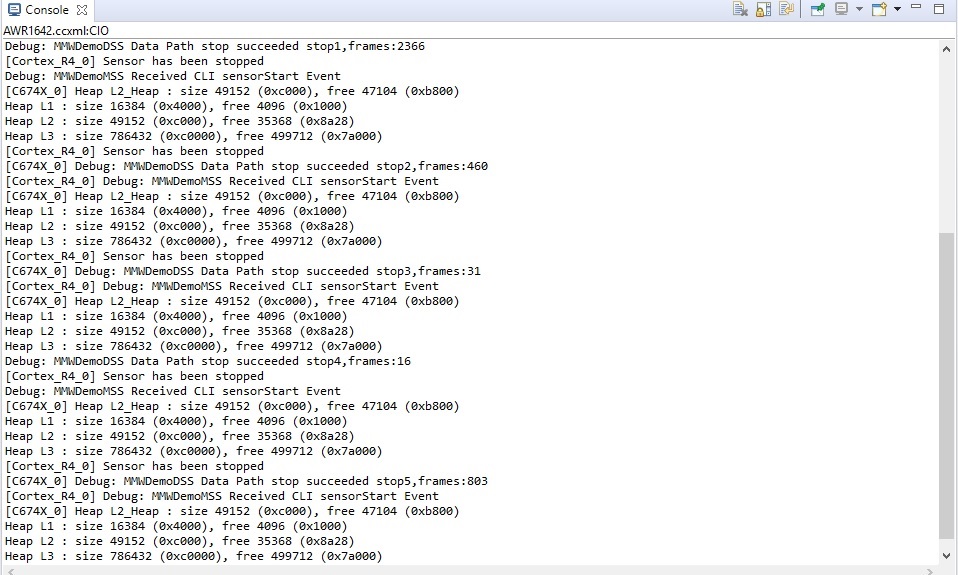

but i seem to have a problem getting the Board to operate at any higher temperature than 40 degrees C. It stops sending CAN Data and freezes until the the power is cycled.

i know there are temperature sensors built into the Radar SOC that are monitored by the RTOS could the problem be here?