Other Parts Discussed in Thread: TMCS1100, TMCS1101

Hello,

I am developing a project using magnets.

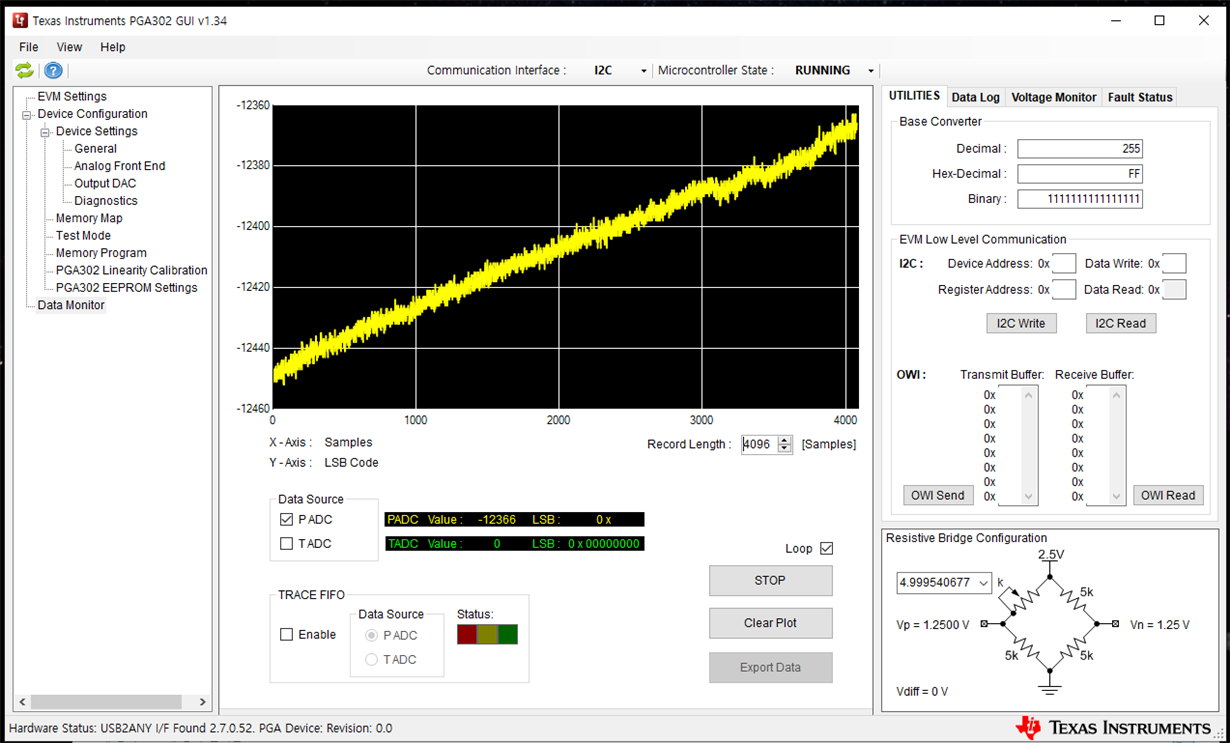

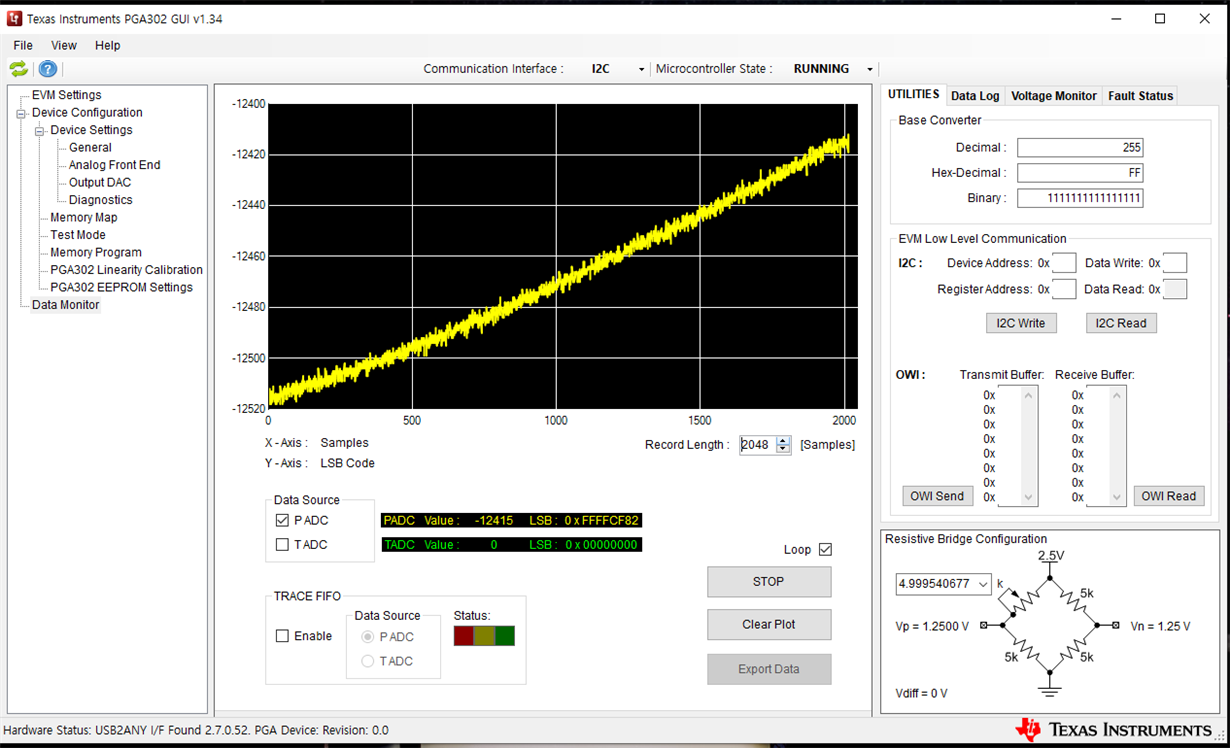

Magnet current is amplified by PGA302 and used.

However, there is a problem that the value increases without any action at the point of 0.

I think it is a drift phenomenon over time.

The products I have to develop have to be very precise.

I need a product that can keep the value constant even if it is still using magnets.

In addition, it must be a product that requires automotive certification.

We are looking at TMCS1100, TMCS1101 products.

I am making a product in which mcu works by reading Alnico magnets with a Hall sensor.

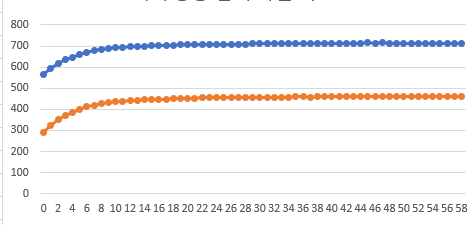

I added additional graphs.

The x-axis is time and the y-axis is the AD value read from mcu.

There is a problem that the value keeps rising for about 0~10 minutes on the graph.

Can the PGA302 solve this problem?

I need a product that can keep the value read from the Hall sensor.

Please introduce a product that you are satisfied with.

thanks.