Other Parts Discussed in Thread: FDC2114, FDC2214,

I made a hollow circle with a very yellow short copper wire and attached it to channel 2 as a single-ended sensor , as shown below.The circle is about 3cm in diameter.

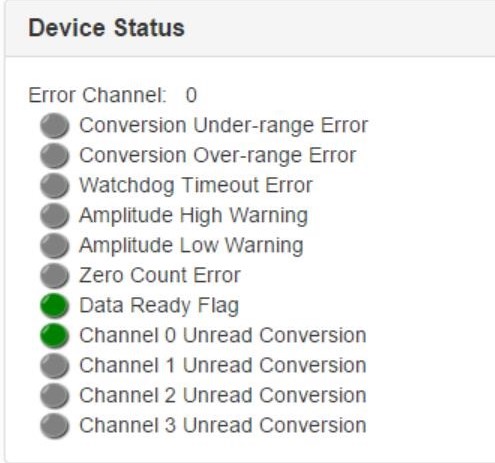

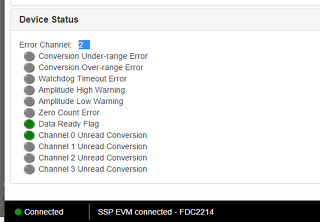

And I checked "Enable" of channel 2 in Sensing Solutions EVM GUI. I found some phenomena that I can't figure out.

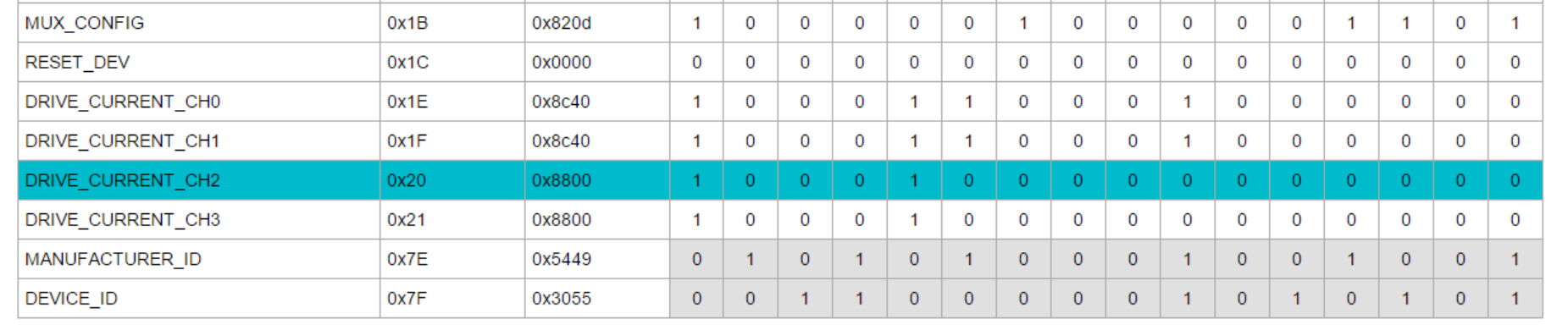

1. When I go to check the value of the registers, vaue of register "DRIVE_CURRENT_CH2" is "0x8800" while values of register "DRIVE_CURRENT_CH0" and register "DRIVE_CURRENT_CH1" are both "0x8c40". why are these registers' values different? Does it influence the sensor although the drive current is same?

2.In the "Configuration" screen ,"Error channel: 2" is displayed below "Device Status" bar. Is there any error in channel 2?

I can't find any information about this in the FDC2114 and FDC2214 EVM User’s Guide.Then, how to solve it?

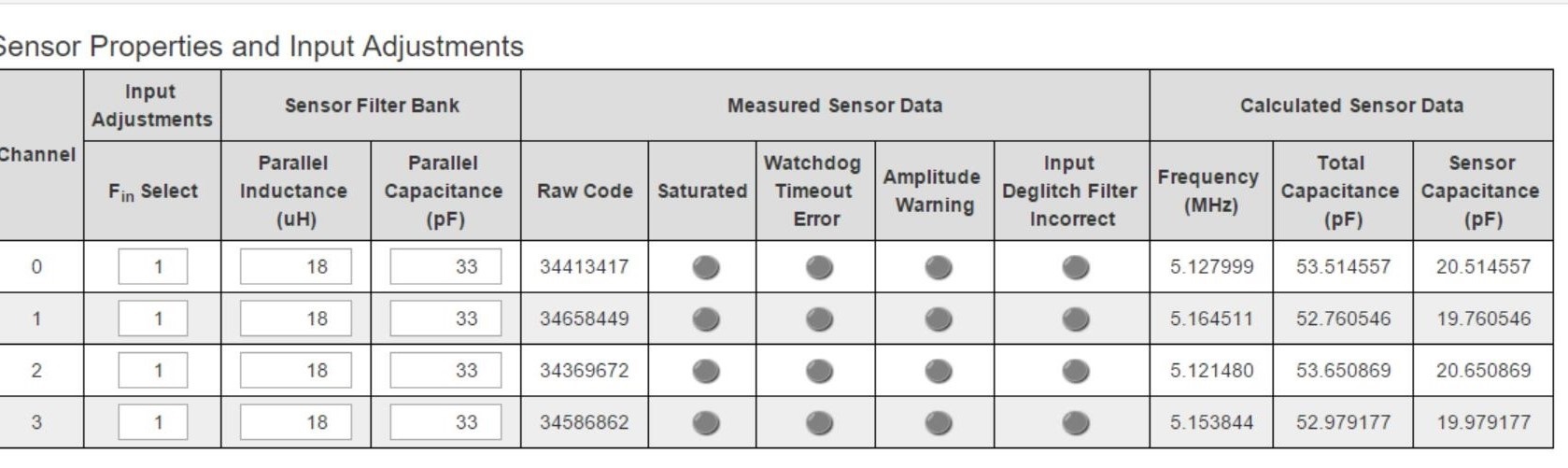

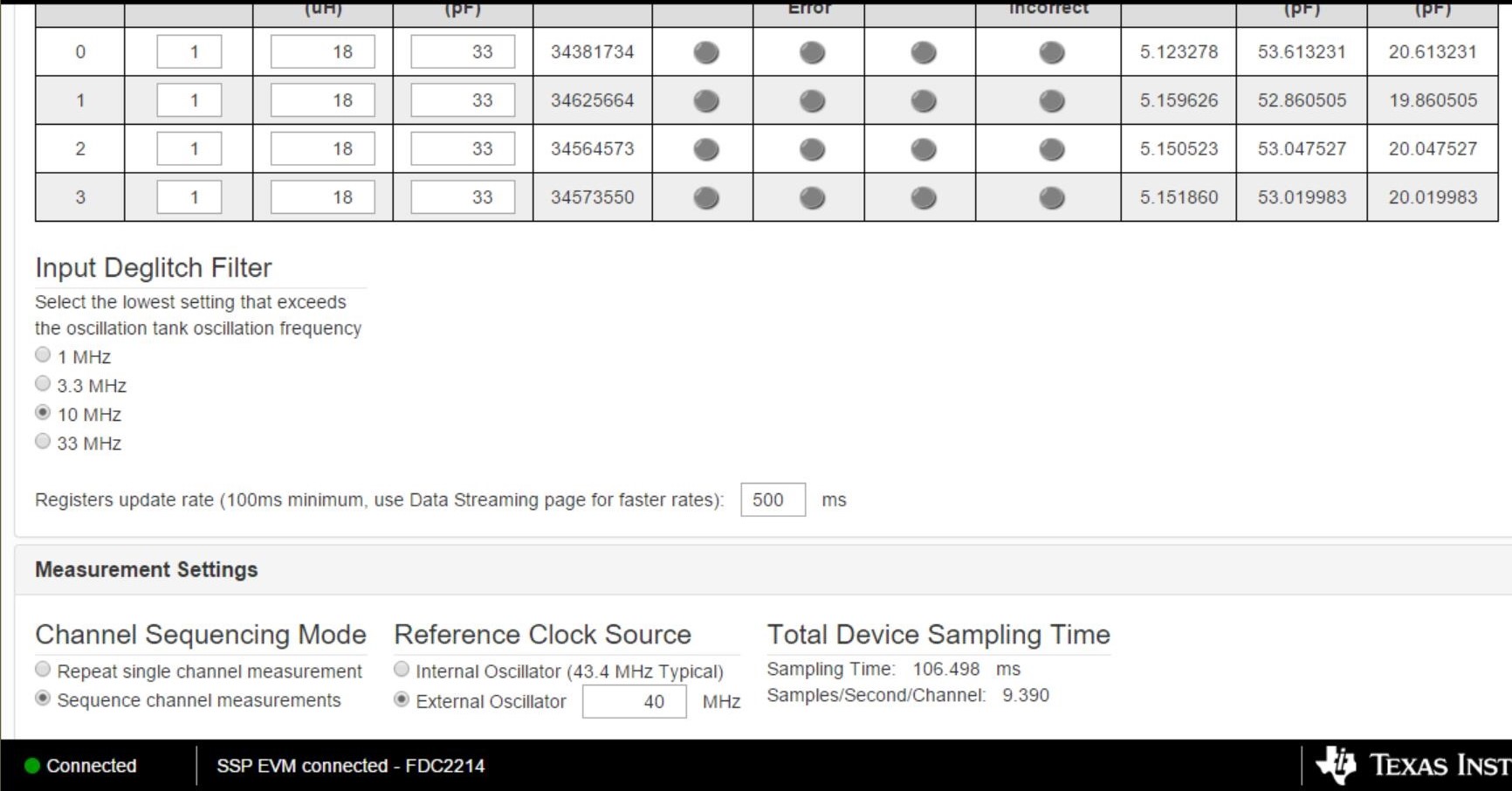

3.After I remove the copper circle from channel 2,the raw code of channel 2 is as same as without removing it. How to explain it? And I find that channel 2 shows a parasitic capacitance of about 20 pF regardless of which sensor is connected or not. Is this correct?

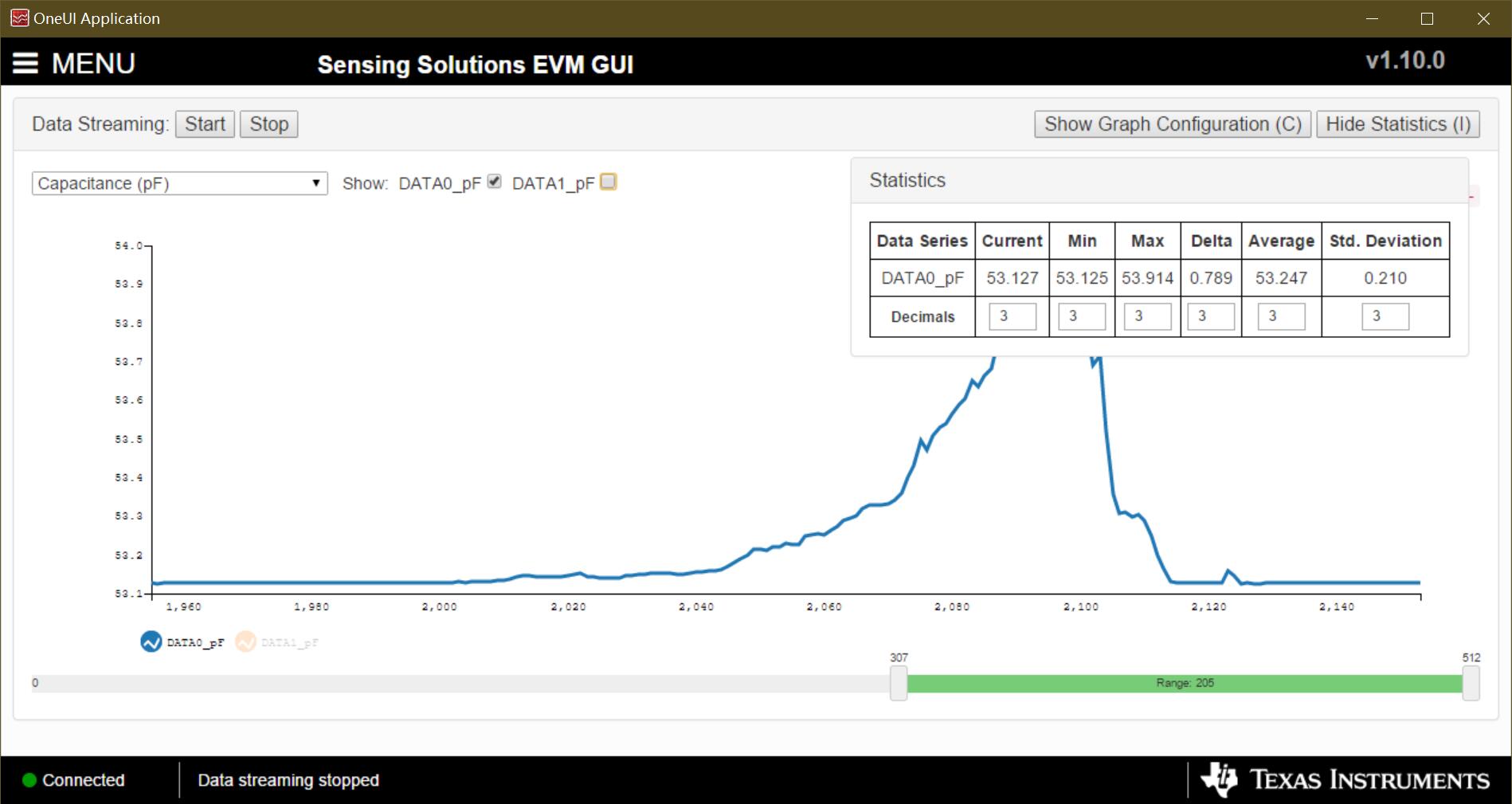

4.I used sensor connected to channel 2 for some simple tests. I thought of my hand as a target object to approach the sensor and get some results. I let my hand to approach the sensor from about 10cm away, and when the distance reached about 4cm, the capacitance curve of the sensor began to increase visibly. According to the data getted from GUI, the maximum capacitance difference is about 15fF, and I don't make sure that it meet the SNR ?

Regards.