Other Parts Discussed in Thread: BOOSTXL-TUSS4440, CSD88537ND, PGA460

Hi,

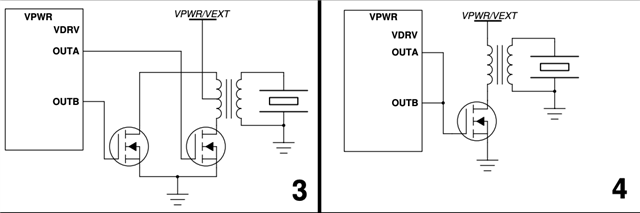

is there a circuit recommendation to drive the TUSS4470 with external mosfet/transformator to drive a 100W transducer?

The 12V battery voltage is available to connect to the circuit and i think i would have to use the internal mosfet to drive the external mosfet circuit right?

Because the direct drive mode will not be able to supply 8A output current using the internal mosfet right?

What would be the best approach then 3 or 4?

And what mosfet and transformator could i use to drive the transducer at 100W?

Bets regards,

Michael