Hi team,

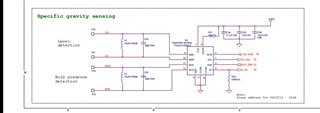

We are facing emission problem during conducting RE . 4,2 Mhz frequency is seen . This may be due to tank circuit of Capsense IC FDC2212 . Enclosing the schematic for the same. L3, L4 form tank circuit . V3P3 is IC supply 3.3 v Kindly review .

Enclosing the board file (layout ) for review ..U4 is the FDC2212 IC ,with L3 ,C32 ; L4 C33 tank circuit.

Can we try by reducing this operating frequency in terms of Khz ( instead of Mhz ) to reduce the noise. Will it work & have any effect on system performance ( capacitor measurement )?

Best regards,