Hi together,

after analyzing the TLV type 2 (MMWDEMO_OUTPUT_MSG_RANGE_PROFILE ) data that is transmitted via UART, I have the following questions:

1. To what exactly are these values relative to? As they are labeled "power", can I somehow assign absolute mW/dBm values to the peaks?

2. Is the data obtained by one or multiple (virtual) receive antennas? If the latter one, how is it guaranteed that an object on the side is not "smeared" over distance as a consequence of different path distances?

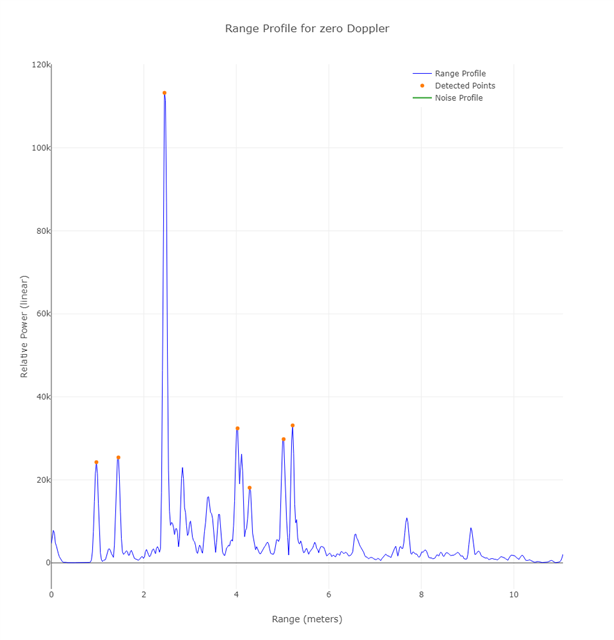

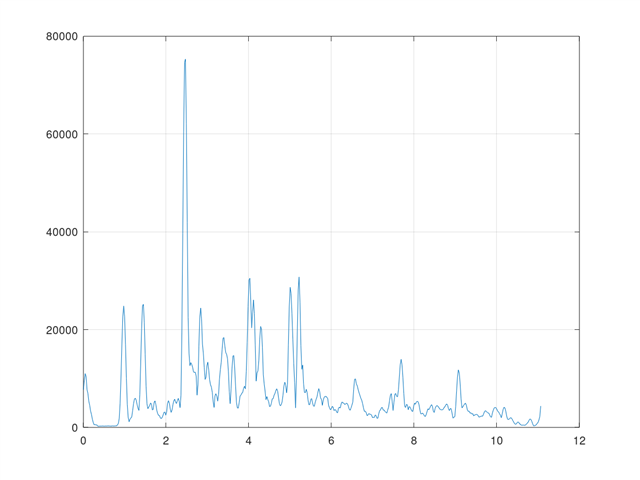

3. I tried to plot the TLV data, but this results in different values than the ones the Visualizer is depicting. As you can see below, while the first two peaks have almost identical values in both plots, the largest peak has a value of more than 110k in the Visualizer's plot and less than 80k in my own plot. Where could this difference come from?