Hi,supports,

After the power supply injection, the case that humidity becomes 100%RH all the time sometimes occurs like a figure of the attachment. This case happens at the frequency once in about 30 times. In this case, the temperature changes with an appropriate value.

<control procedure>

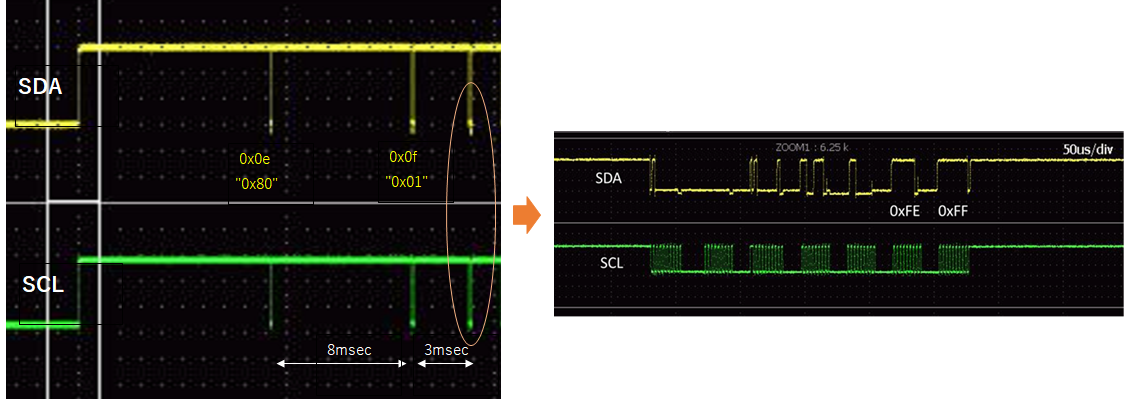

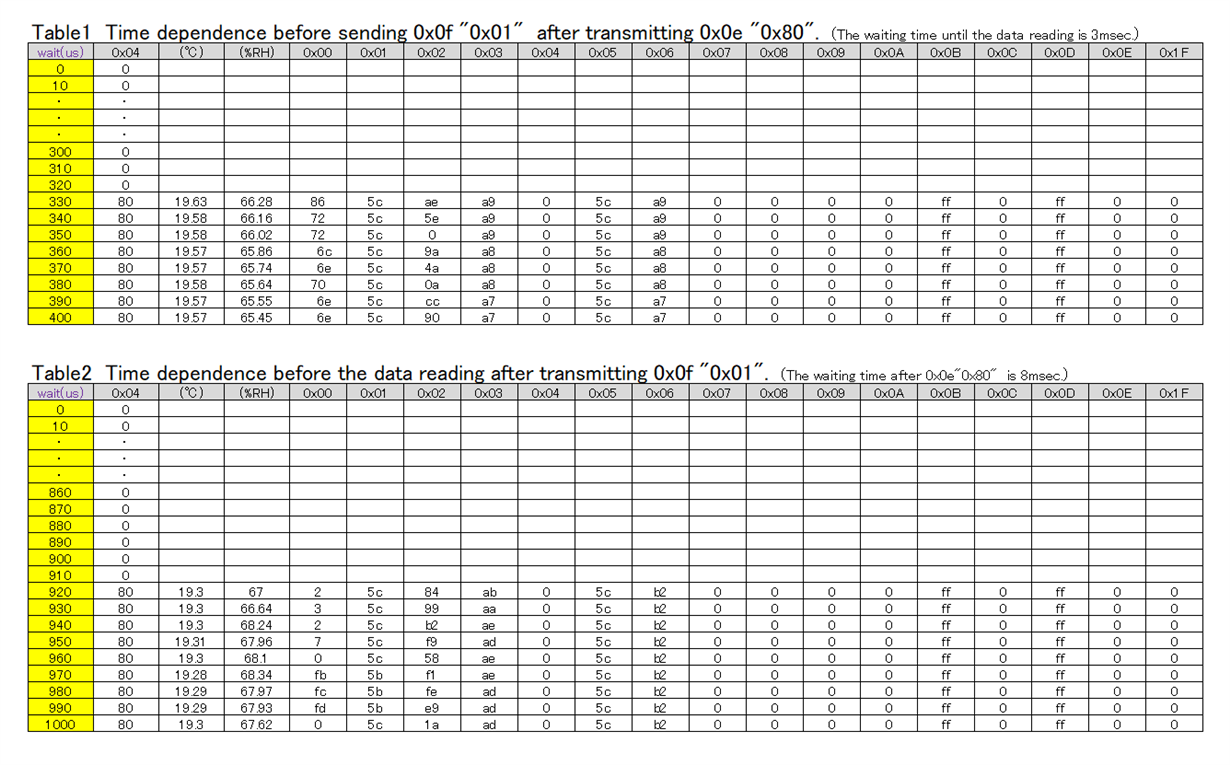

Add 3.3V --(900msec)--> write 0x0e "0x80" --(8msec)--> 0x0f "0x01" --(3msec)--> data read … wait…

(repeat : 0x0f "0x01" ----> data read … wait …)

I would like cooperation for cause investigation.

1. I think that power-on reset does not work normally.

Please tell me the detailed specifications when I turn on HDC2010.

2. In the following Web address, there is an additional procedure at the time of the power supply injection(0x45"0x04"), but do you think that it is associated with this matter?

3. After a trouble occurs, the humidity can get away from 100%RH if I initialize the register again.

Does 0x0e "0x80" carry out another activity as well as the initialization of the register?

I do not understand a reason to be improved by the initialization of the register.

Regards,

Toshi