Other Parts Discussed in Thread: DRV8305, MOTORWARE

Hello

I am using lab5b for speed control at increasing levels of max current limit.

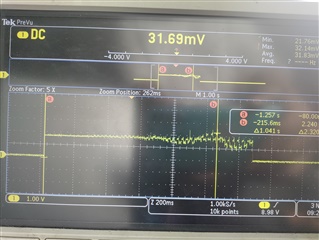

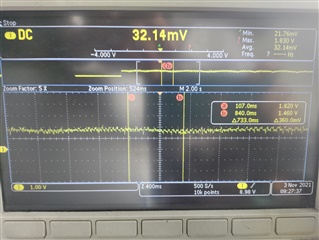

When the max current limit is kept beyond 15A(20A - 25A), the control is getting rolled over after a certain stall is applied on the motor.

I have changed the USER_IQ_FULL_SCALE_CURRENT_A and USER_ADC_FULL_SCALE_CURRENT_A to 82.5A and 165A respectively owing to sense resistor of 2mohm.

Are there any variables that need to be adjusted so that the control doesn't get rolled over(the motor control stops when stall is applied on the motor).

P.S i have tested Lab5a on the board and the same issue happened at 23A for 7mohm sense resistor. So, I changed the USER_IQ_FULL_SCALE_CURRENT_A and USER_ADC_FULL_SCALE_CURRENT_A to 82.5A and 165A for 2mohm sense resistor and then, it worked. There was no stopping of motor control.

But now, even after changing those parameters, the problem still remains and is happening at 15A itself.

I have already used lab2c for user parameter identification and it worked correctly.

Please Help.

Thanks.