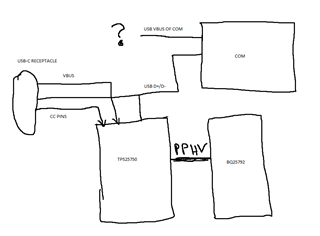

Other Parts Discussed in Thread: TPS25750, USB2ANY, BQ25792

Hello!

I am a beginner with electronics design after about 12 years my electronics engineering degree.

Could anyone be helpful to review my schematic attached as pdf?

Best Regards.PowerSupplyV0.8.pdf