Other Parts Discussed in Thread: ULC1001, DRV2901

Hi,

Q1.

I have tried many times to download ULC1001_GUI_v2p3p6.zip, but it always fails. Is it possible to send the zip file directly to me?

Q2.

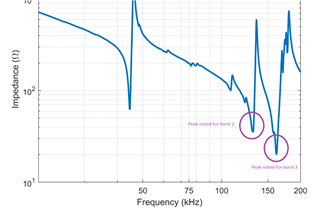

Am I correct in understanding that the role of IV sensing is used for temperature estimation and mass detection?

Is the temperature estimated by measuring the change in impedance of the piezo in terms of current value? The algorithm for mass detection is not clear.

Q3.

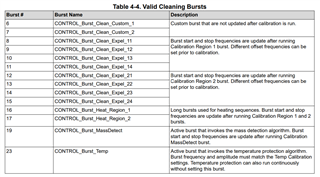

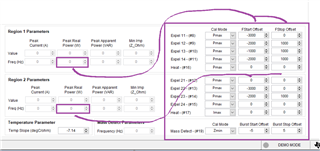

Why are there two different frequency settings for cleaning bursts: region 1 and region 2?

Q4.

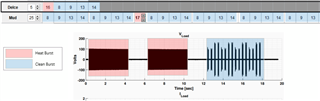

Can you tell me why there are two heating bursts in the Deice Cleaning Profile within the ULC1001 datasheet.

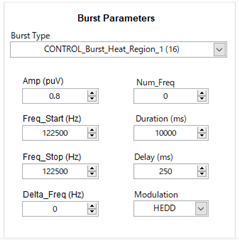

Looking at the default settings in the GUI, it appears that 'CONTROL_BURST_Heat_Region_1' is set to one BURST.

Q5.

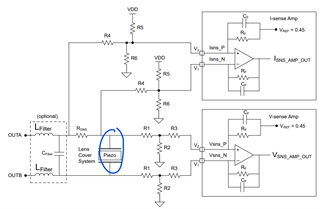

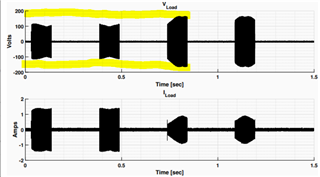

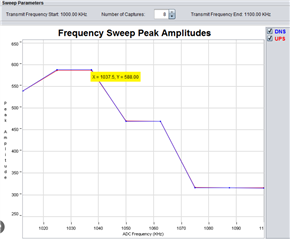

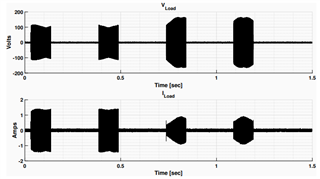

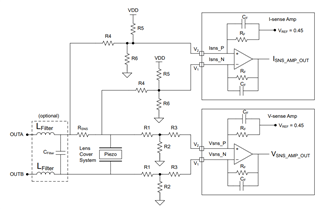

Are [mV] and [A] the correct units for the voltage and current values in this diagram?

Also which specific areas are VLOAD and ILOAD measuring in the diagram below?

Q6.

Is there any information on failures and reliability regarding the ULC? I am wondering, for example, how much durability testing a Customer should do before a mass production shipment is made.

Thanks,

Conor