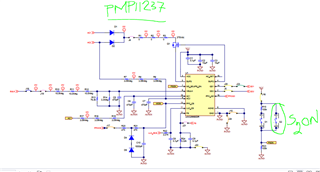

Other Parts Discussed in Thread: UCC29950, , PMP, PMP11237

Hi TI,

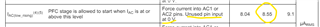

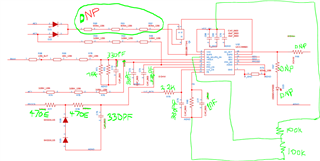

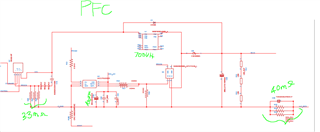

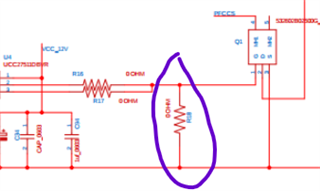

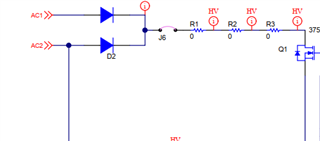

good day. I'm designing 300W SMPS with UCC29950D (with auxiliary bias mode). this is my reference from TI PMP11303. as per your recommendation 1st I'm starting with the PFC section. but the PFC-GD not delivering the PWM. The ucc29950 giving issue. but im giving all those inputs properly. kindly provide us with test methods to check if IC working or not and also any other predefined input values in pins that will provide us with an output, to check if pin functionalities are working properly and also provide us support on generating the PWM output signals.