Other Parts Discussed in Thread: SFRA, UCC21710-Q1, UCC21710

Tool/software:

Hello,

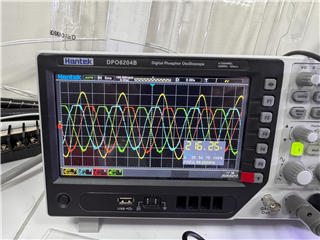

Please tell me, because we want to provide greater power, we changed the CASR 15-NP to CASR 50-NP of U3/U4/U5

Is there anything that needs to be adjusted in the software?

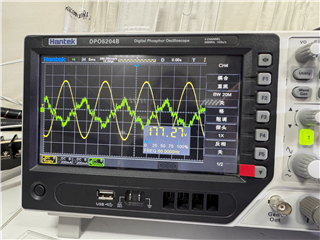

Because the values now read from TINV_iGrid_A_sensed_Amps / TINV_iGrid_B_sensed_Amps / TINV_iGrid_C_sensed_Amps are only about half of the values asured by the instrument?

Sorry to trouble you, thank you