Other Parts Discussed in Thread: PMP41062, BQ25731, TPS25750, TPS25751

Tool/software:

Hi TI team,

I hope you all are doing well. I have a few questions about PMP41013, or alternative reference designs / controllers if they are available, for a powerbank application.

For said powerbank, the Li-ion cells I'm getting are 32Wh each, so I'm limited to just 3 cells in series (3S1P config). At a 60W output and minimum battery voltage of 2.9V/cell, that is a ~7.5A input current assuming 90% efficiency. At a 100W output, that is a >14A input current, and I already know that efficiency would inevitably be closer to about 80% at this point.

Ideally, the power circuitry could allow the battery to output 60W - 100W through the USB-C port in source mode, the higher the better. For sinking (charging the battery) 45W is ok.

Now, I would like to ask - PMP41013 claims to be able to output up to 60W, however the graphs and thermal views are only shown at a battery voltage of 18V, or the nominal voltage of a 5S pack. The efficiency would only get worse as the difference between the input and output voltage got larger, so can the system still output that 60W in USB-C source mode from a battery voltage as low as 8.4V?

Of course, a 100W output would be preferred, but PMP41062 is only compatible with 4 - 10 cell batteries. I do not mind what sort of heatsinking I might have to do, or how wide the PCB traces have to be - could I create a powerbank based on PMP41062 that would be compatible with 3 cell batteries with an 100W output, 45W input?

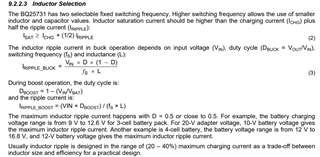

If either are true, please let me know what modifications I would need to make to component values (I would imagine the inductor would need to be bigger?), PCB layout, and/or thermal considerations to get started with this design.

Thank you very much. Have a great week.

Kind regards,

Rain