Other Parts Discussed in Thread: TIDM-02010,

Tool/software:

Hello,

I would like to understand the significance of below motor parameters and how does it impacts motor operation

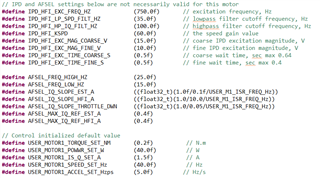

USER_MOTOR1_FLUX_EXC_FREQ_Hz

USER_MOTOR1_FREQ_NEARZEROLIMIT_Hz

USER_MOTOR1_FORCE_DELTA_A

USER_MOTOR1_ALIGN_DELTA_A

USER_MOTOR1_FLUX_CURRENT_A

USER_MOTOR1_TORQUE_CURRENT_A

USER_MOTOR1_ACCEL_RUN_Hzps

USER_MOTOR1_SPEED_FS_Hz

USER_MOTOR1_GAIN_SPEED_LOW_Hz

USER_MOTOR1_GAIN_SPEED_HIGH_Hz

What are these parameters for? Aren't we using Align method to find rotor position? Then why we need to use IPD settings here?

What are these parameters for? Aren't we using Align method to find rotor position? Then why we need to use IPD settings here?

and why there are additional parameters like USER_MOTOR1_Ls_d_COMP_COEF, USER_MOTOR1_Ls_q_COMP_COEF, USER_MOTOR1_Ls_MIN_NUM_COEF and many others are used in TIDA-010265 reference design and not used in TIDM-02010 reference design. The motor control software should be same for both right?