Other Parts Discussed in Thread: BQ25792, BQ24617, BQ25792EVM

Tool/software:

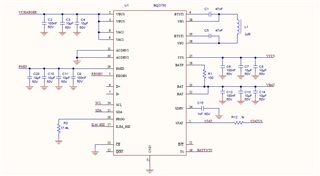

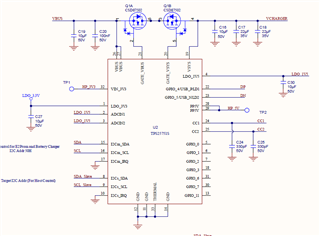

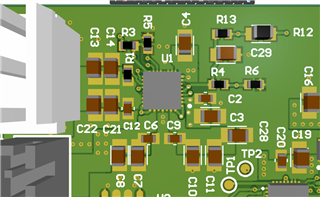

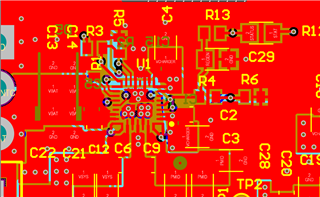

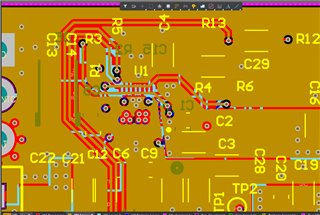

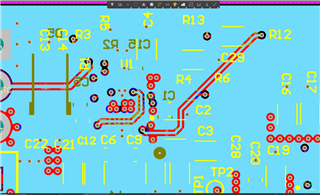

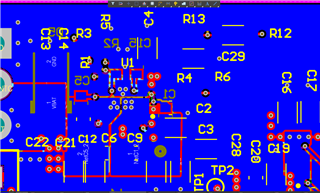

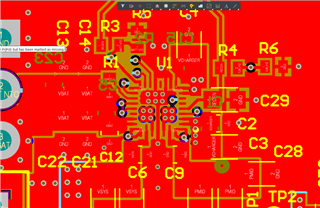

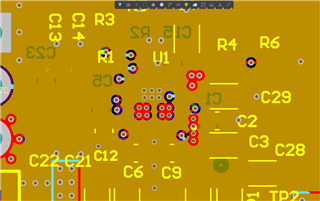

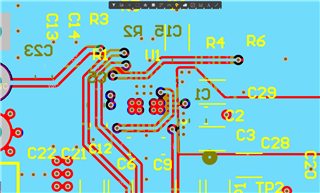

I'm implementing the TIDA050047 design using the TPS25751S Bus controller with the BQ25792 Charger IC for a 4S2P battery charger system. I've set the firmware up for the following parameters:

Configuration: TPS25751S Sink Only with BQ

Maximum Power Sourced: Disabled

Maximum Power Sinked: 45W

Preferred Role: Disabled (Power Sink)

USB Highest Speed: No USB Data

Preferred Data Role: Disabled

Suport BC 1.2: NO

Support Liquid Detection: NO

Vendor ID USB-IF: Use TI's

Product ID: Use 0x0000

Charger to Integrate: BQ25792 (series)

Percentage Above PD Contract Current: 10%

Percentage Below PD Contract Voltage: 10%

Battery Charging Voltage 16.4V

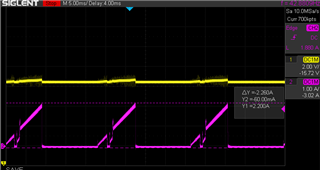

Battery Charging Current: 2A

Charger Termination current: 120mA

Precharge Current: 120mA

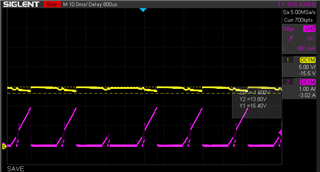

Dead Battery Clear Threshold: Disabled

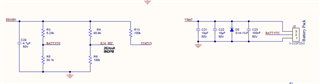

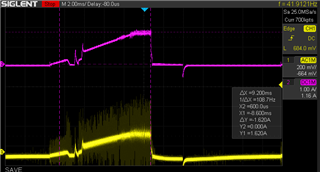

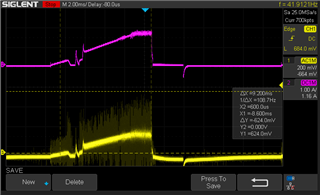

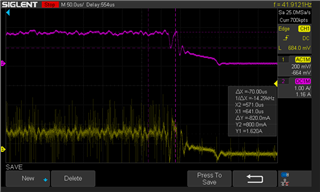

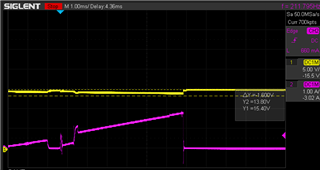

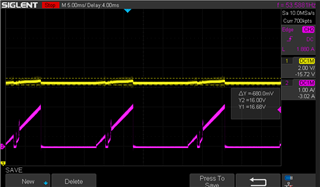

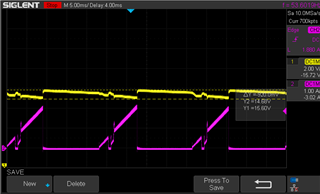

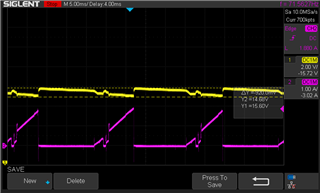

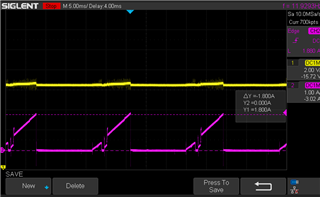

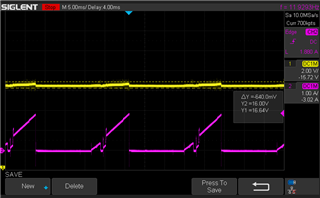

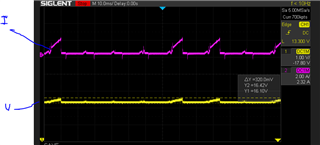

and I'm charging with a 65W PD charger that is supplying 15VDC VBUS per the protocol. I have an odd thing happening towards the end of the charge cycle. When the battery charge gets up to around 15.8VDC the charger starts going in and out of charge indication. The charge current peaks to around 1.8A with indicates to me tha tit should be in the Constant Voltage charge mode on the decaying charge current curve. When the current peaks, it is pulling the voltage at the battery connector up to 16.4VDC and seems to shut down.

It stays doing this slowly charging the battery up until it hits around 16.2VDC as measured with a meter, then it falls back to constant voltage with the current slowly decreasing as expected and a constant indication of charging until fully charged. I'm not sure what would be causing this.