Hi all,

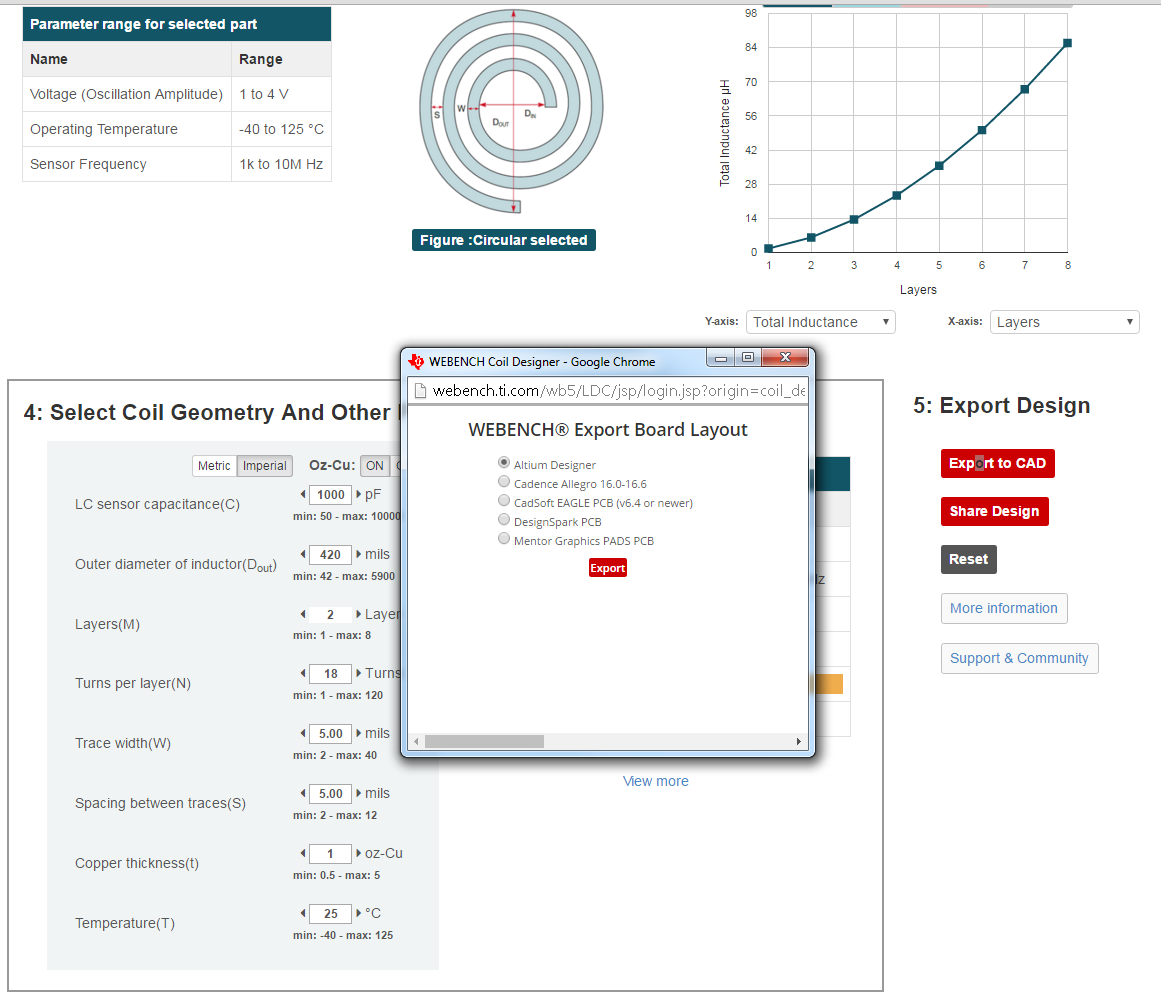

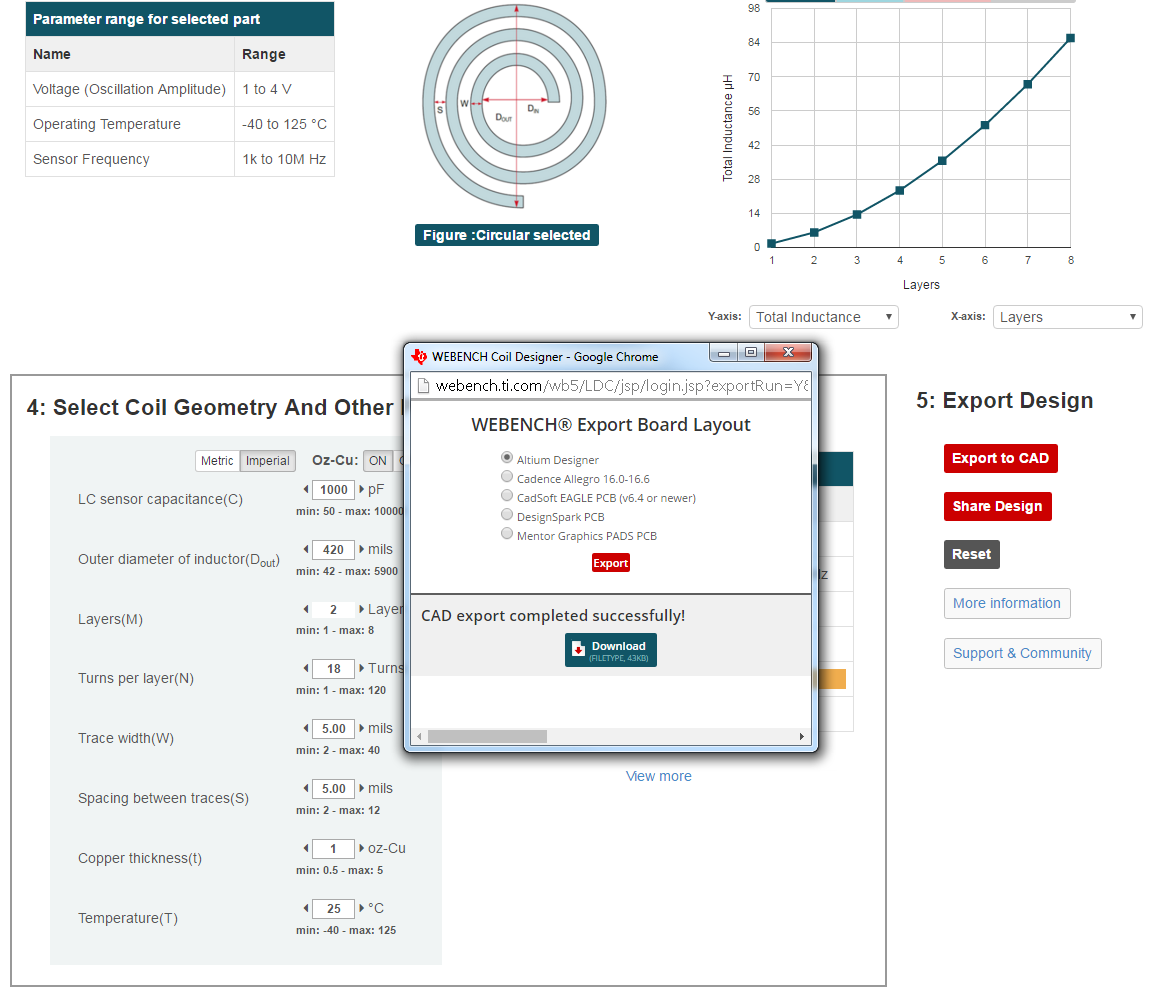

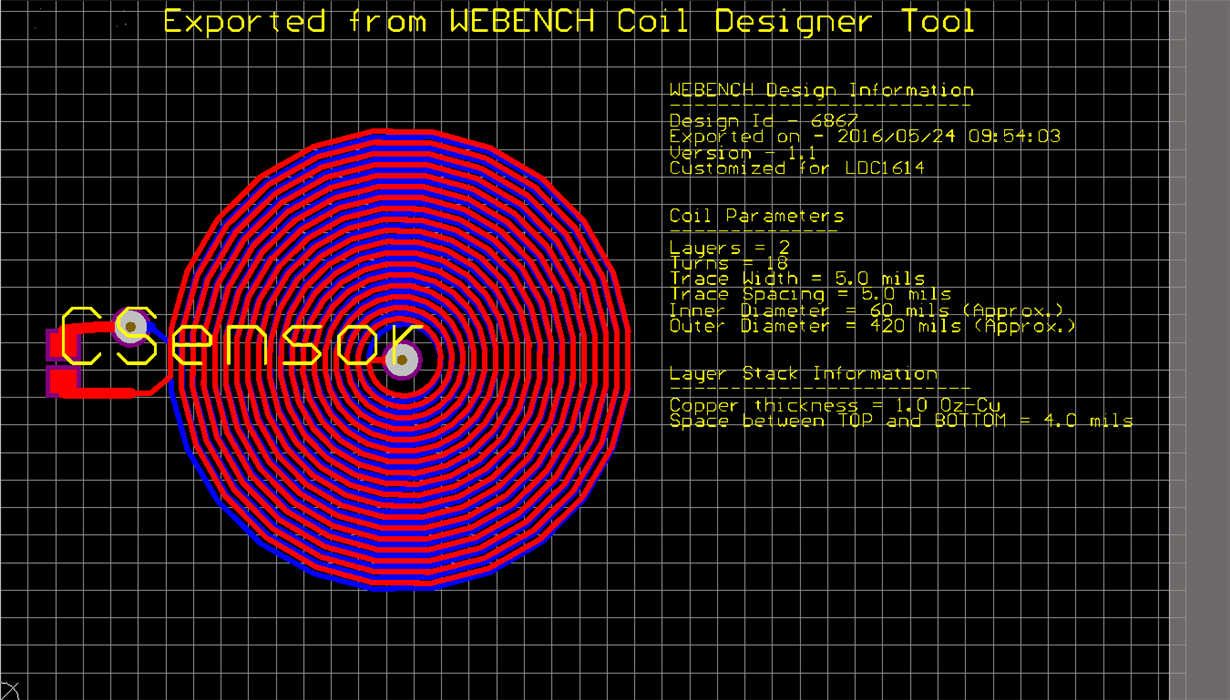

I would like to export coil design through webench.

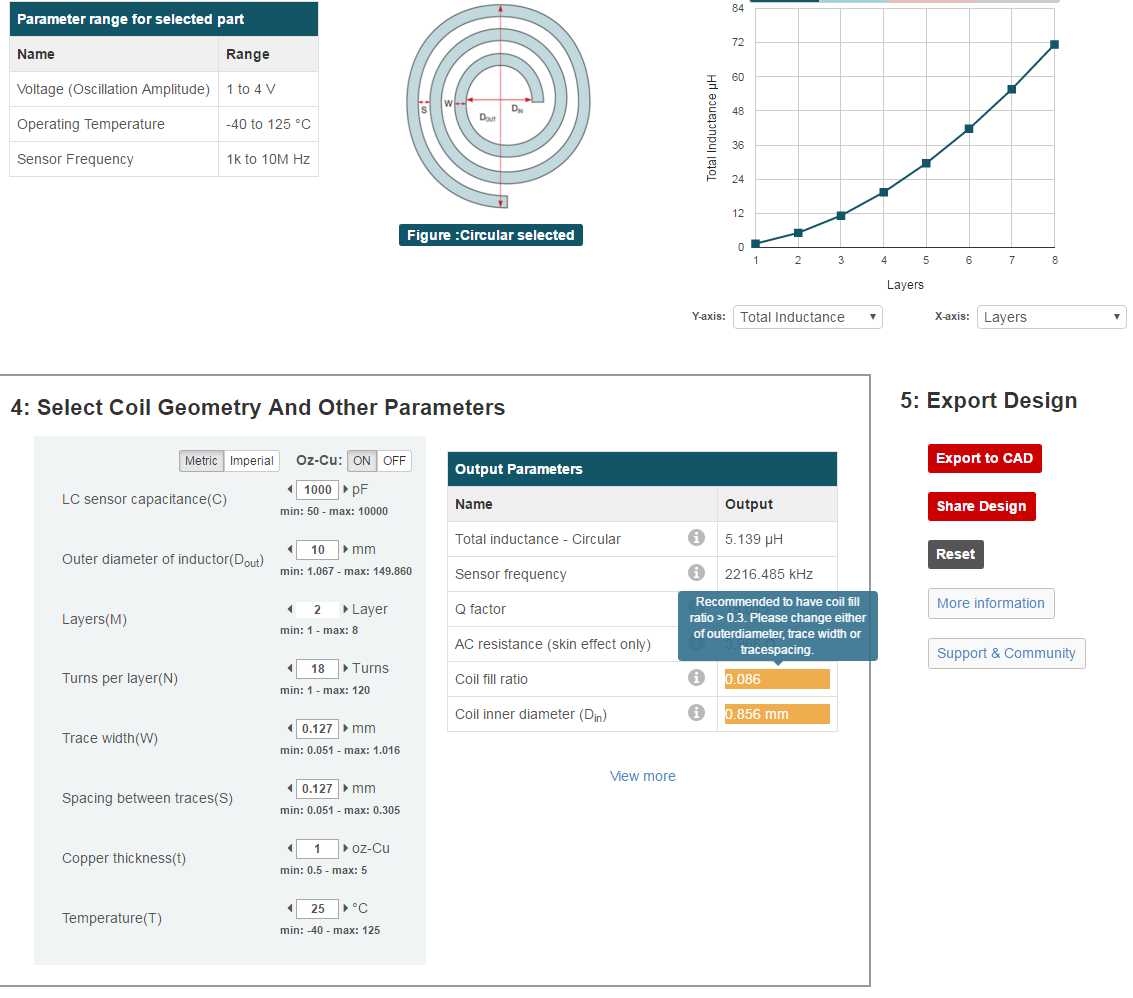

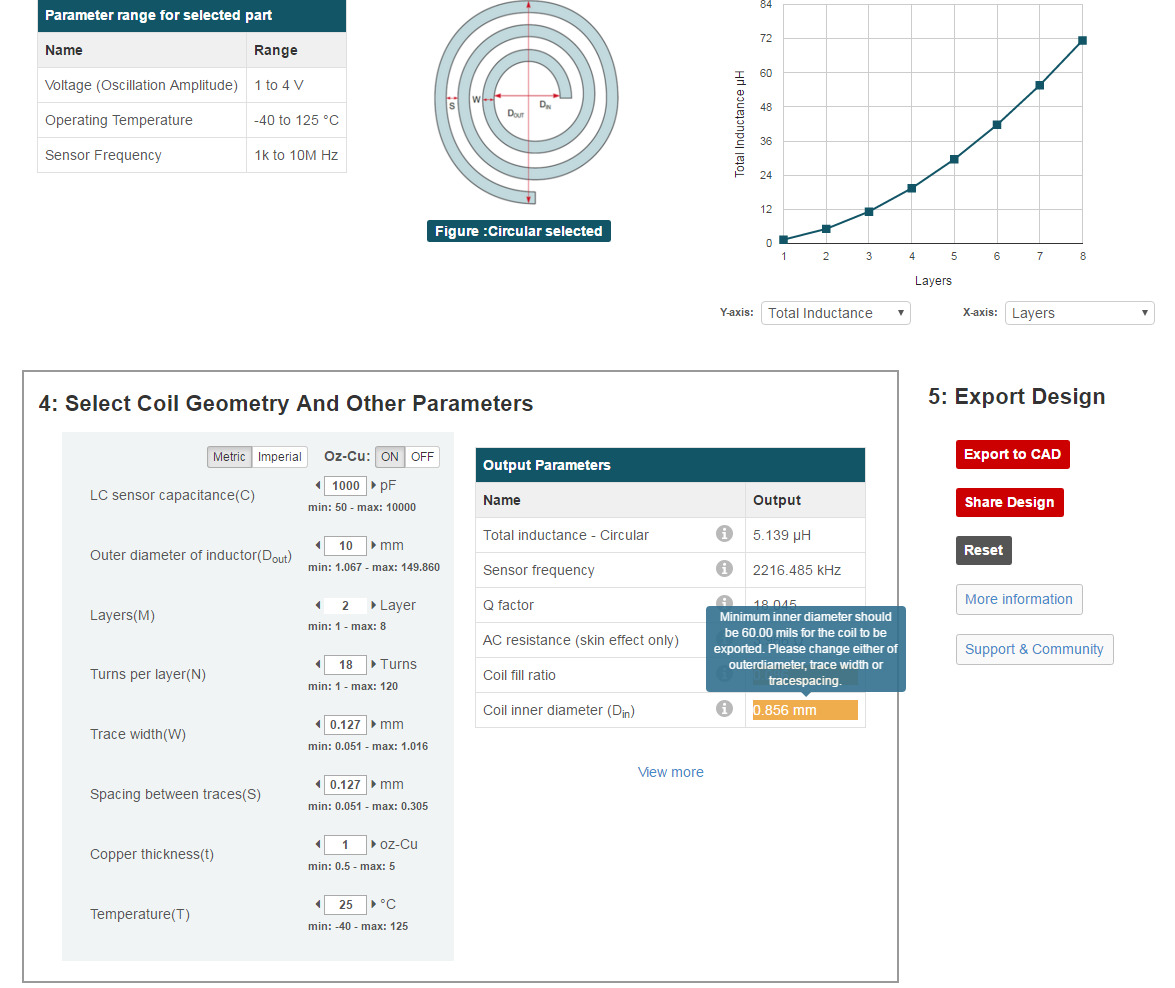

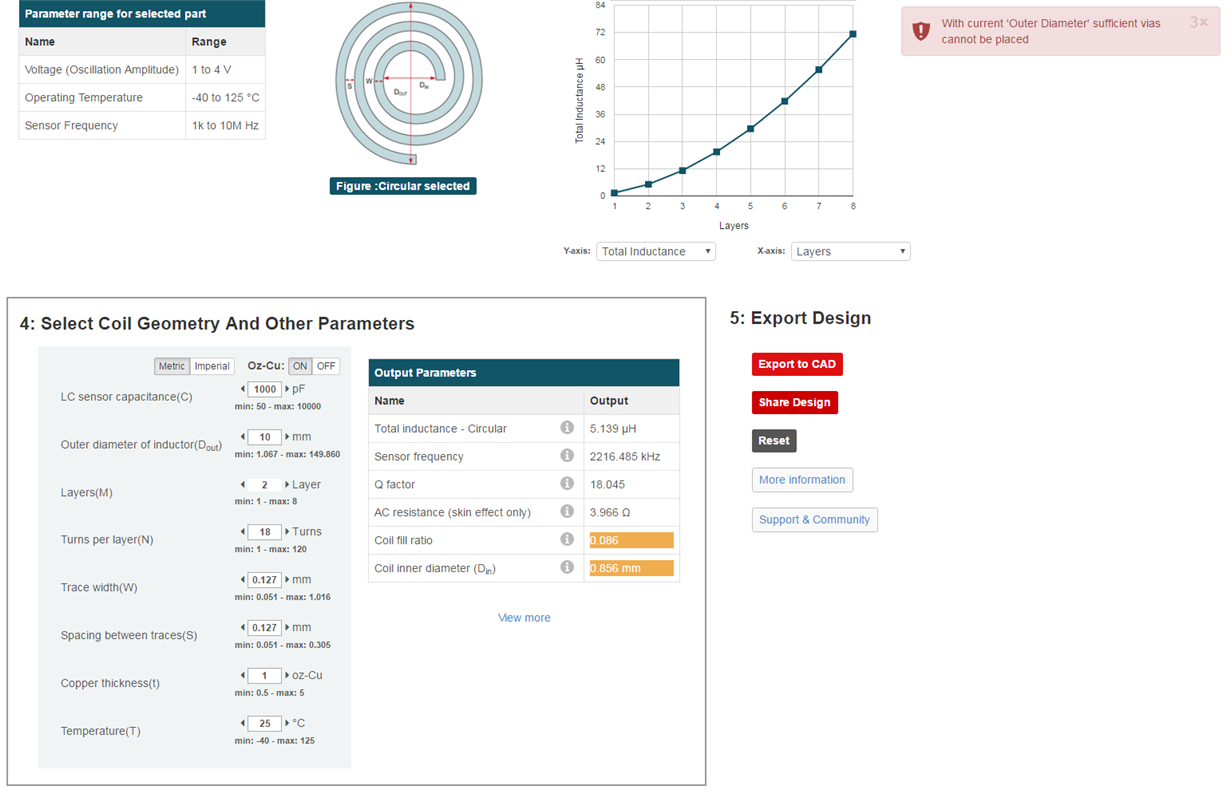

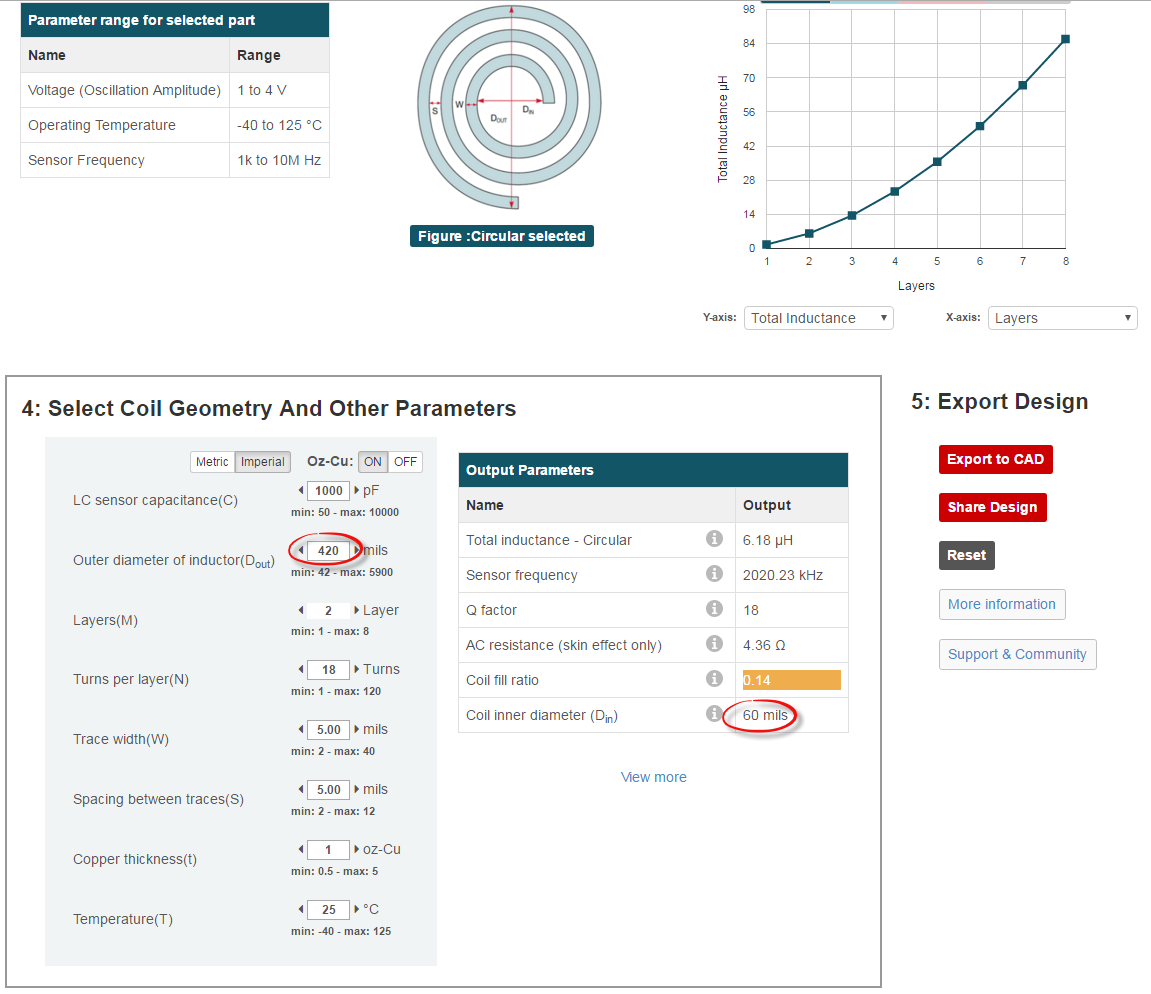

As below picture, if coil inner diameter show the warning, I cannot export to CAD about this design. However, LDC application engineer said that coil inner diameter doesn't impact on the performance. The most important thing is to increase the inductance.

To increase the inductance as larger as possible, the coil inner diameter should be smaller.

Would you let me know how to export to CAD despite of the warning?

Thanks in advance.

Best regards,

Sammy