Tool/software: WEBENCH® Design Tools

hello !

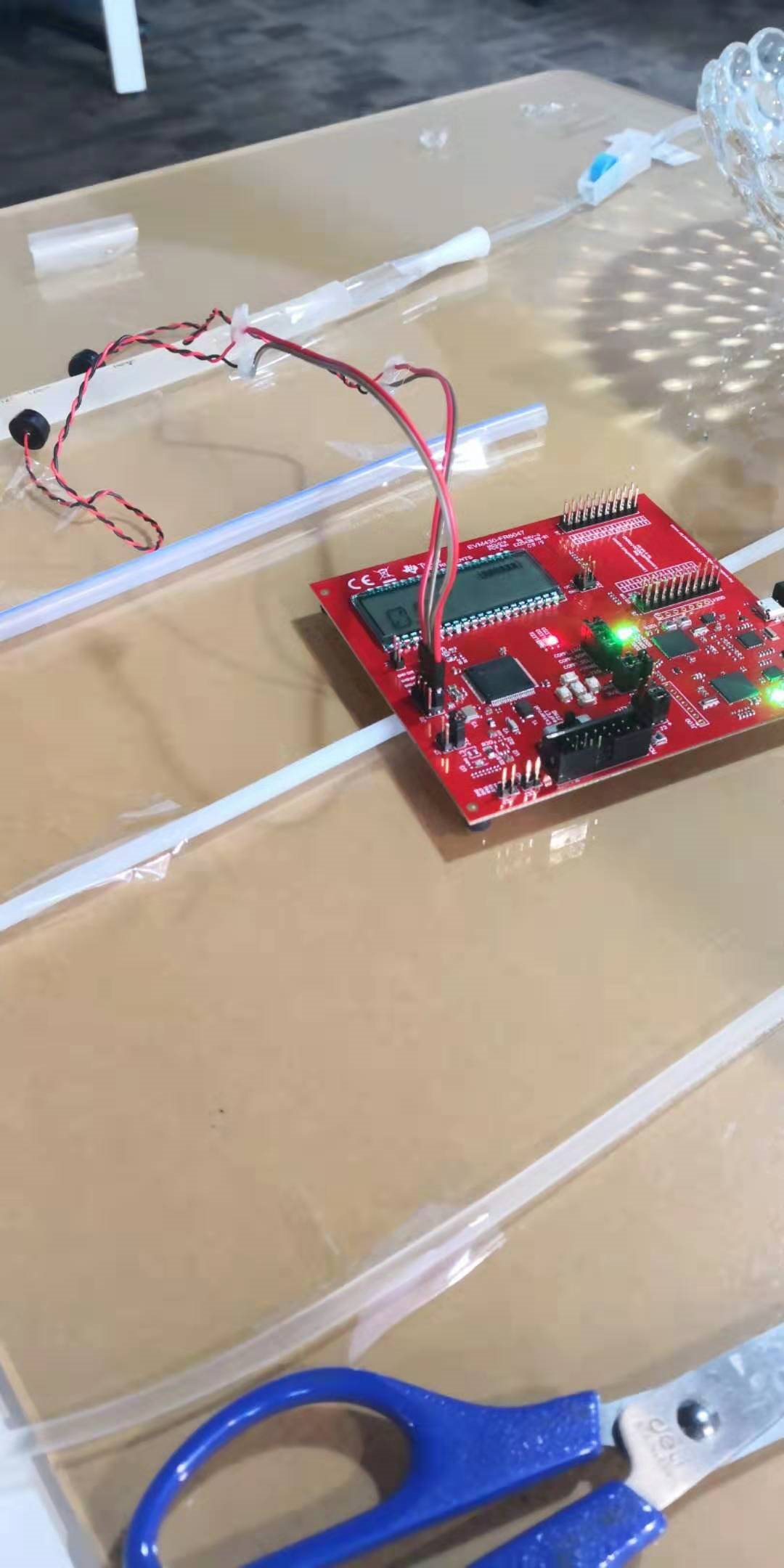

hardware:MSP430FR6047 Ultrasonic Sensing Evaluation Module

software:CCS9.0.1, USS_02_20_00_15

The most common error is “No signal detected in up and downstream channel”. This error usually has one of two root causes:

- The strength of the signal being read into the USS algorithm with the current configuration is too low to use

- The meter is currently disconnected

I‘m sure The meter is currently connected,May be The strength of the signal is too low.

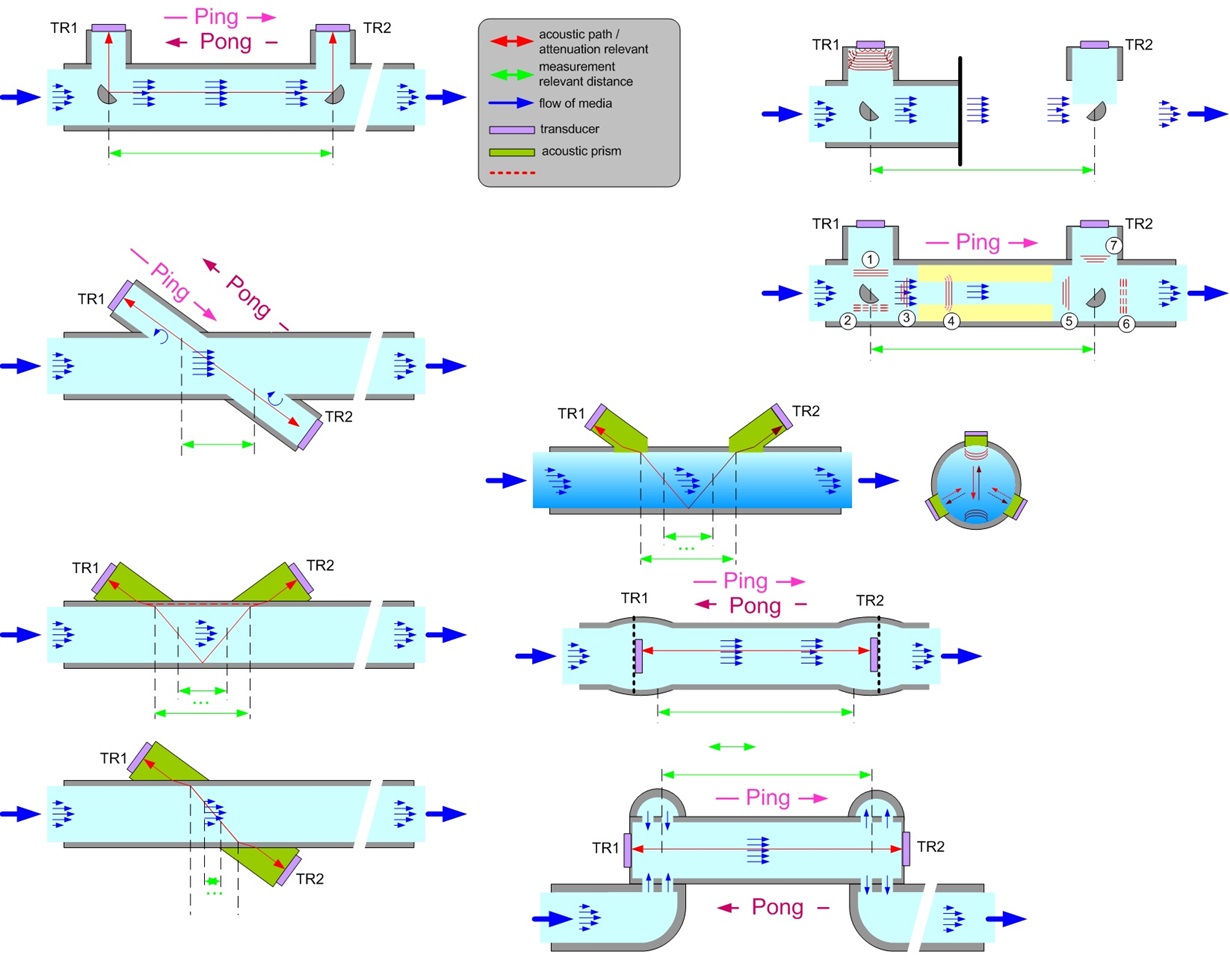

My application scenario is to measure the velocity of the infusion line from outside the tube,The ultrasonic probe manufacturer says the probe should not be used for flow measurement outside the tube.

Therefore, I would like to know whether there is a suitable ultrasonic probe suitable for my application scene, can you recommend it?