Tool/software:

Hello TI,

I am using CC2650 Custom PCB based on Launchxl-CC2650 design.

BLE SDK 2_02_07_06

CCS7.4

Compiler TI Ver.5.2.6.

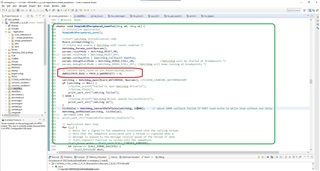

Base example code - Simple BLE peripheral.

We have designed "Electronic shelf lable" product using CC2650.

All devices are tested at our end completely multiple times. We didnt see any problem in its functionality before dispatching them to customers.

We had sent few devices to our customers on 6 Jun 2024.

Devices are being sent back to our office since they are not working after few days.

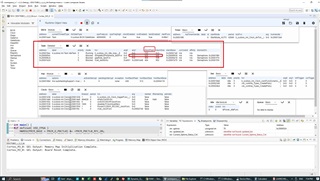

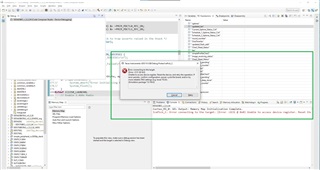

When I received the device, I connected the device into CCS debugger as guided in the ble_user_guide for "Connect the debugger to a running target".

response after connecting the debugger is shown in the attached image.

"Unable to access the device register, Reset the device retry the operation".

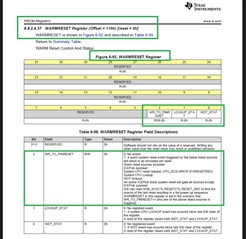

So I disconnected the device battery pack (CR2450X8 ) and reconnected it again.

After reconnecting the battery pack, device started advertising and also started working properly.

I had to HARD RESET the device.

This issue is being seen in many devices running on same firmware.

Please help me to find out the root cause and solution...

Thank you,

Dnyaneshvar Salve