Tool/software:

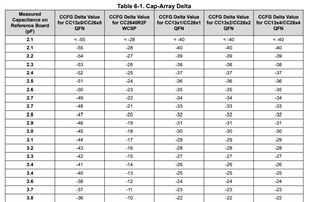

In swra640 we have a table to look up to the cap-array delta value and the measured capacitor bias value:

Where can I find a similar table for CC2340? The Q1 and Q2 value can only be positive in SmartRF Studio 8, which is different than CC26xx.

Best regards,

Shuyang