Tool/software:

Hello.

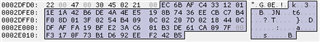

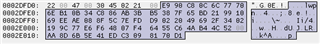

When you build the SDK sample program "basic_ble_oad_onchip", xx_v1.bin and xx_v2.bin are output.

This bin file is different every time I build it, and I don't understand why that is. What's different?

I think there is a bin output setting in the post-build steps, does this have anything to do with it?

The SDK is simplelink_lowpower_f3_sdk_8_20_00_119.