Tool/software:

We are developing an application that uses BLE and ADC using CC2651R3SIPA .

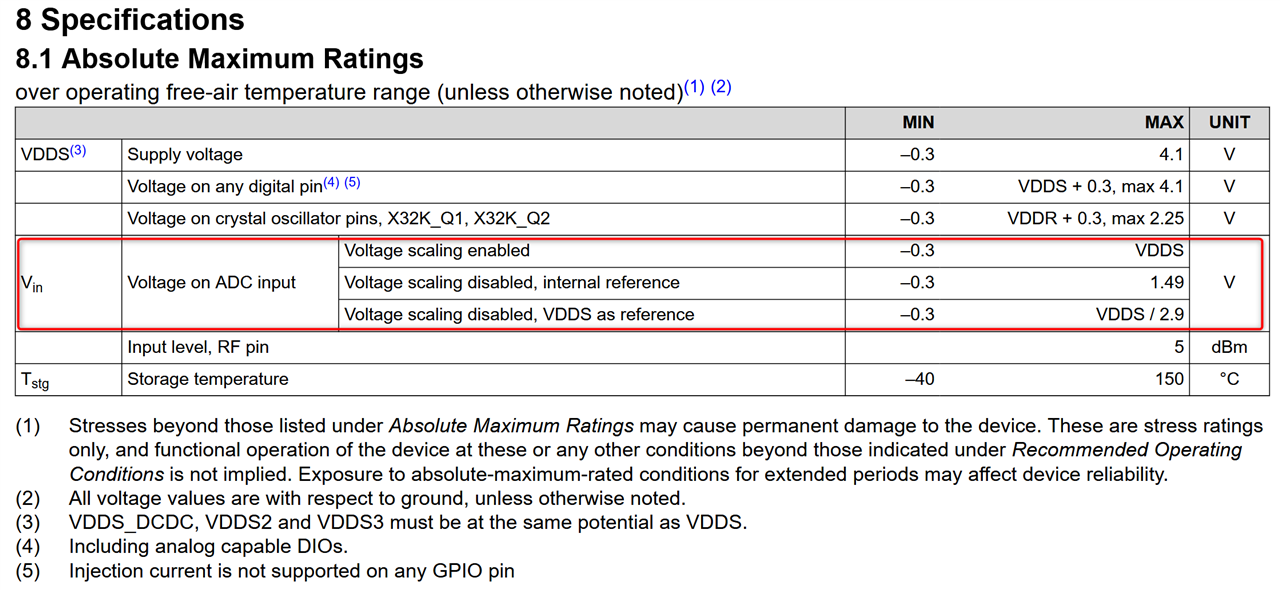

In the CC2651R3SIPA, the power supply pin for operation and the ADC reference voltage pin are integrated. We want to achieve an ADC accuracy of 0.5% or less. However, considering the supply current (around 100mA), there are no LDOs with 1% accuracy that meet this, and reference voltage ICs with 0.5% accuracy (with an output current of about 20mA) do not provide enough supply current for operation.

Do you have any suggestions on how to improve the ADC accuracy by increasing the ADC reference voltage accuracy?

Alternatively, are there any power supply ICs that can meet the required supply current and provide 0.5% or better accuracy?