Other Parts Discussed in Thread: UNIFLASH

Hello,

I have a customer with an issue with their CC2640R2F custom board. The application is a battery application where the battery is epoxied to the hardware so it is not removable. The system lives in one of 3 states: shelf, awake, and active. The idea is that while it is in "shelf" mode it will be ultra low power and be able to wait for the customer to wake it up. The system should be able to live in this state for a long time, year(s). The current measurement numbers using the XDS110 with energy trace indicates that this should be doable, measuring ~1-3ua. With the production intent prototype parts they are seeing a significantly higher current draw that is depleting the battery in under 2 weeks. The simple order of operations for building the boards is:

Flash a program that fully disable the chip

Epoxy the battery to the board and let fully cure

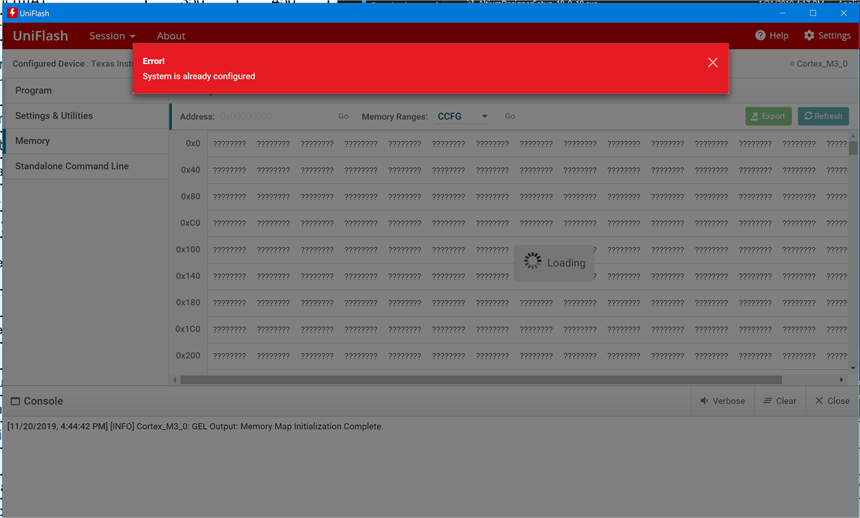

Flash the production code onto the chip

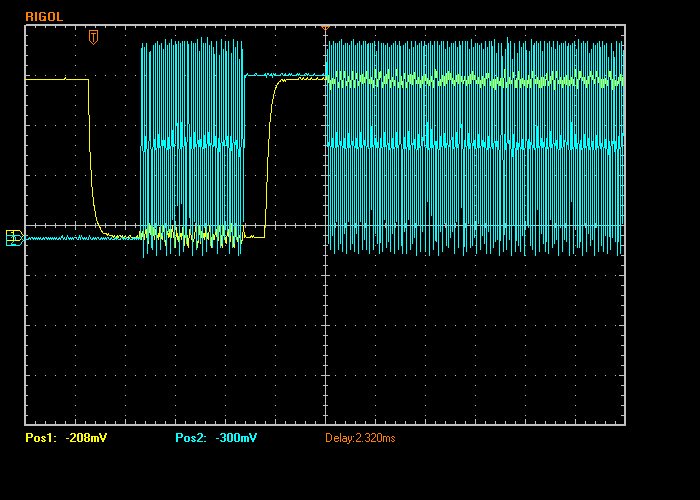

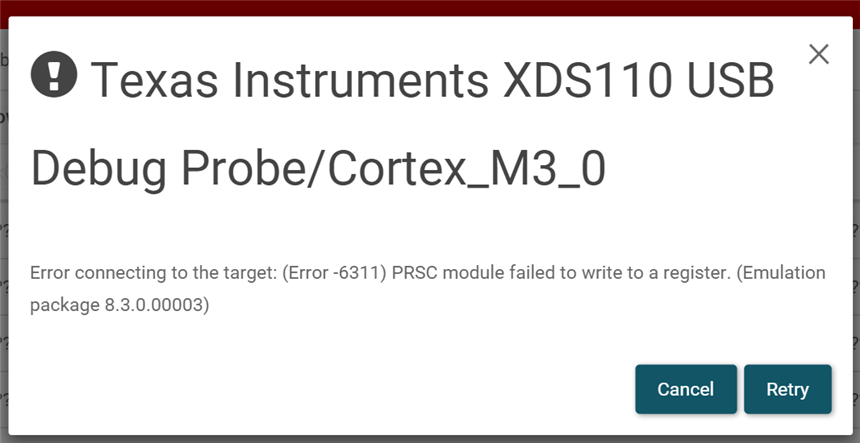

I was able to track the issue down to the way the chip is left after the part is programmed. The micro appears to be stuck in some sort of active state as apposed to executing the production code. If I force a reset by pulling the reset line on the micro the chip seems to start executing the correct code and function as expected. They are using Flash Programmer 2 and it indicates that it is successfully performing a reset on the chip after successfully programming the chip. I have been able to verify this on multiple parts and multiple times on the same parts.

The customer is able to move forward knowing they need to manually reset the chip after programming. I would like to provide them a solution that doesn't require the manual reset and an answer as to what is happening to the chip during programming.

Thanks in advance for the help!