Hi team,

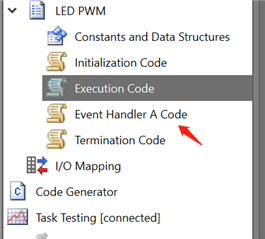

Environment: Sensor Controller Studio. Hardware: purchased development board. Modified routine: LED PWM for LaunchPad.

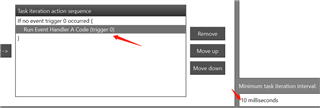

The customer would like to verify the module in the timer2 event trigger section, the copied code in the section is as follows:

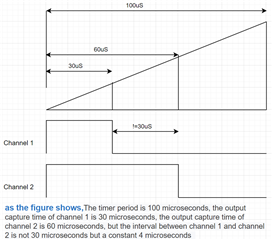

After 1 ms, the timer channel 1 turns on the sensor supply, then channel 2 triggers an interrupt over 1 ms, detects the sensor data inside the interrupt and turns off the sensor supply, and then go into the next cycle.

Change the code as follows: Change the power-on pin to red light and flip the green light inside the interrupt.

Issue: It is now a solid red light, the green light does not turn over, and the customer suspects it does not enter into timer interrupt. What should do next? Does this coprocessor support the imer2 event trigger?

The routine is clearly labeled, completely copied, is there a missing configuration or missing code? The interrupt function is added automatically, using the index as well as the routine is 0.

Could you help check this case? Thanks!

Best Regards,

Cherry