Tool/software:

Hello! I hope this message finds you well.

We are currently facing a technical issue in a project and would like to request your support, in case you have dealt with a similar situation with any customer.

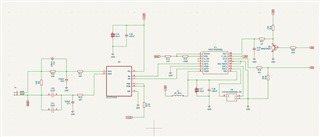

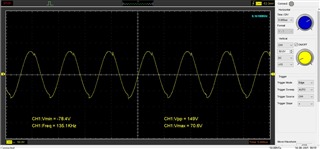

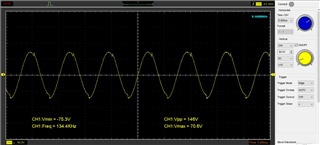

We have developed an RFID reader circuit for animal identification, operating at a frequency of 134.2 kHz, using the TMS3705 transponder. The current average reading range is approximately 20 cm. The circuit consists of the following blocks:

Reading antenna: 220uH Q 21 (dimensions 240 x 240mm) with 2 resonant capacitors of 3.3nF in parallel = 6.6nF, tuned to 134.2 kHz;

Power driver (UCC27424D), responsible for amplifying the signal generated by the TMS3705 and applying it to the antenna;

TMS3705 IC, which performs modulation/demodulation and RFID system control;

Ceramic oscillator (CSTCR4M00G53A-R0), 4 MHz, used as the clock source for the TMS3705;

ATmega328P microcontroller, which interfaces with the TMS3705 (sending and receiving serial data).

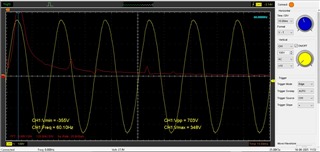

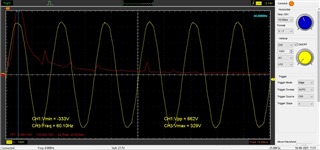

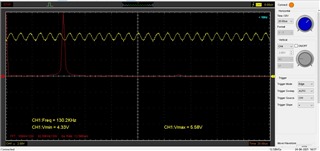

The circuit is powered by a 12 V switching power supply, and the problem arises when electric motors driven by frequency inverters are operating on the same power grid (even if physically distant). In these cases, the transponder's reading range is significantly reduced.

To mitigate this interference, we have already implemented the following measures:

Installation of a passive EMI filter at the power supply input;

Installation of a passive EMI filter at the switching power supply output;

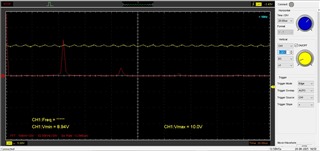

Use of an isolated DC-DC converter from the 12 V output;

Use of shielded cables between the circuit and the reading antenna.

Despite these actions, the issue persists. We have observed a slight improvement in range when using the DC-DC converter, which we believe is due to an additional ground path. In fact, touching the circuit’s GND terminal with a finger also improves the range considerably, which reinforces the electromagnetic interference hypothesis.

At this point, we are out of clear alternatives to solve the issue, and we would like to know if your technical team has any additional recommendations or if you have encountered similar cases in the field.

We look forward to any guidance or suggestions that might help us. Thank you in advance for your attention and support.