We are having troubles with the CC1101 and found an apparent discrepancy on the datasheet for this part.

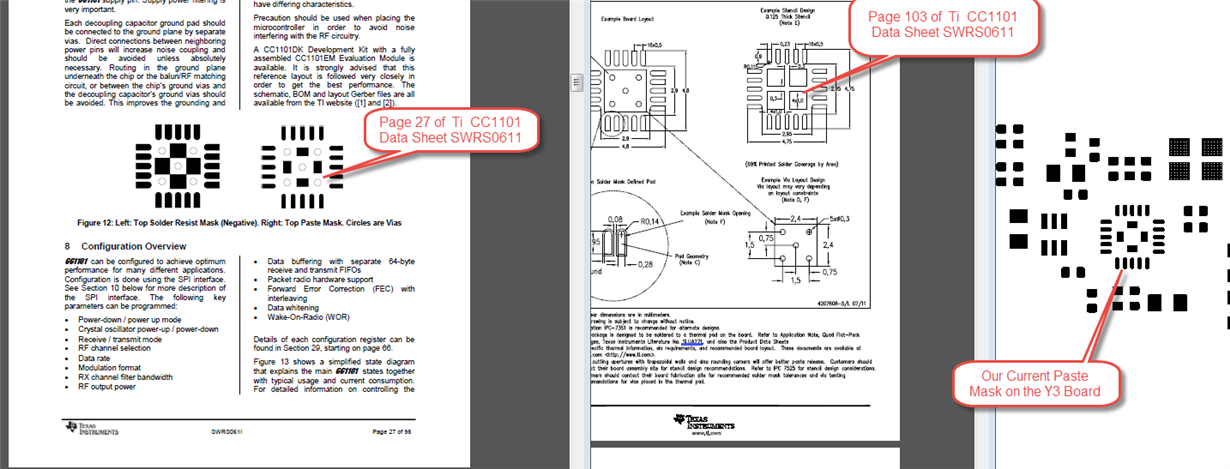

Page 27 of the SWRS0611 seems to indicate a soldermask opening with a square pad located north center, west center, east center, and south center on the center ground slug. This image has no dimensions.

Page 103 of the same datasheet has beautifully dimensioned drawing of the stencil and is a bit vague on the soldermask opening requirements, however given the stencil design, it is possible to imply intended soldermask requirements. It seems that this drawing is more detailed and specific and in accordance with many other device stencil/solder attach designs.

Since we are having production issues with this, we are investigating any area where there is area for concern. Since my first review of this design, I have been concerned with this exposed pad and stencil strategy.

I have attached an excerpt from your datasheet for reference. I would like to get an explanation of which method is preferred and a rationale for using each type of both are acceptable. It appears that both thermal and RF ground would be better served by the stencil/pad design on Page 103.

Looking forward to a comment from TI.

I have attached an excerpt from your datasheet for reference. I would like to get an explanation of which method is preferred and a rationale for using each type of both are acceptable. It appears that both thermal and RF ground would be better served by the stencil/pad design on Page 103.

Looking forward to a comment from TI.