Other Parts Discussed in Thread: , CC1350, SYSCONFIG

Dear all,

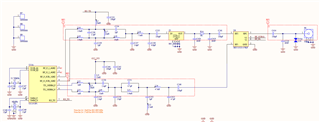

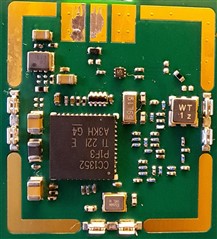

We are developing RF communication system with cc1352P. Hardware is realized on a custom board that is referenced to LAUNCHXL-CC1352P1 swrc349a. Everything is going along nicely, but when added RSSI measurement feature noticed one important issue with RF noise floor.

We checked systems self-induced RF noise floor with antenna removed and noticed that different boards have noise floor at different level, ranging from -98dBm to -82dBm. The same boards when runned from TI smart RF Studio via debugger port has consistent noise floor around -107dBm. CC1352P configuration is taken from 1Mbps 868MHz preset, exported from TI Smart RF Studio. I made sure that all complimentary microcontrollers, power supplies and functional blocks of the system are running and active in all test to keep the same environment. I triple checked that configuration in smartrf_settings.c and smartrf_settings.h are same as in original files exported from TI software.

We then tried implement long range 5kbps 868MHz mode to gather more data and noticed that in this long range mode there is no scattering in RF noise floor. It is consistent throughout all boards. With our custom FW it is around -122dBm. When running from TI Smart RF Studio around -127dBm. This few dB difference can be explained by the fact that we are using different averaging method. What concerns is the scattering in 1Mbps mode.

Can someone direct me what to try, where to look to find the cause of scattering?

Best regards