Other Parts Discussed in Thread: CC1310, CC1312R

Tool/software:

Hi

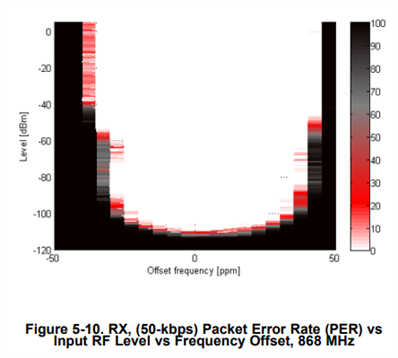

In my system I have basicaly two type of device: network manager (NM) and end unit (EU). GFSK modulation, 50kBits/s, RF band 868MHz.

The NM run on a TI CC1312R1 LaunchPad. EU run on a CC1312R7 LaunchPad or on a real (custom) HW with CC1312R7.

The communication between devices looks like to work OK (frames are received, CRC pass, decryption pass, and ACKs are send back).

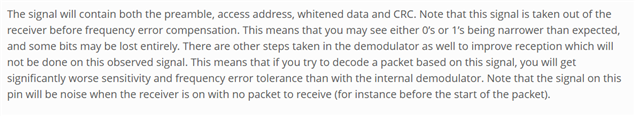

The Issue is that the demodulated RX data output by RF cores of both NM and EU looks very strange in case that EU runs on a custom HW.

Any ideas what could be wrong?

Screenshot from a logic analyzer to show you the signals:

Regards,

Dimitar