Hi.

First of all, I want to say that my radio knowledge is not very advanced, so perhaps I will say some nonsense and surely I can't see the point where any advanced radio pro can just in seconds.

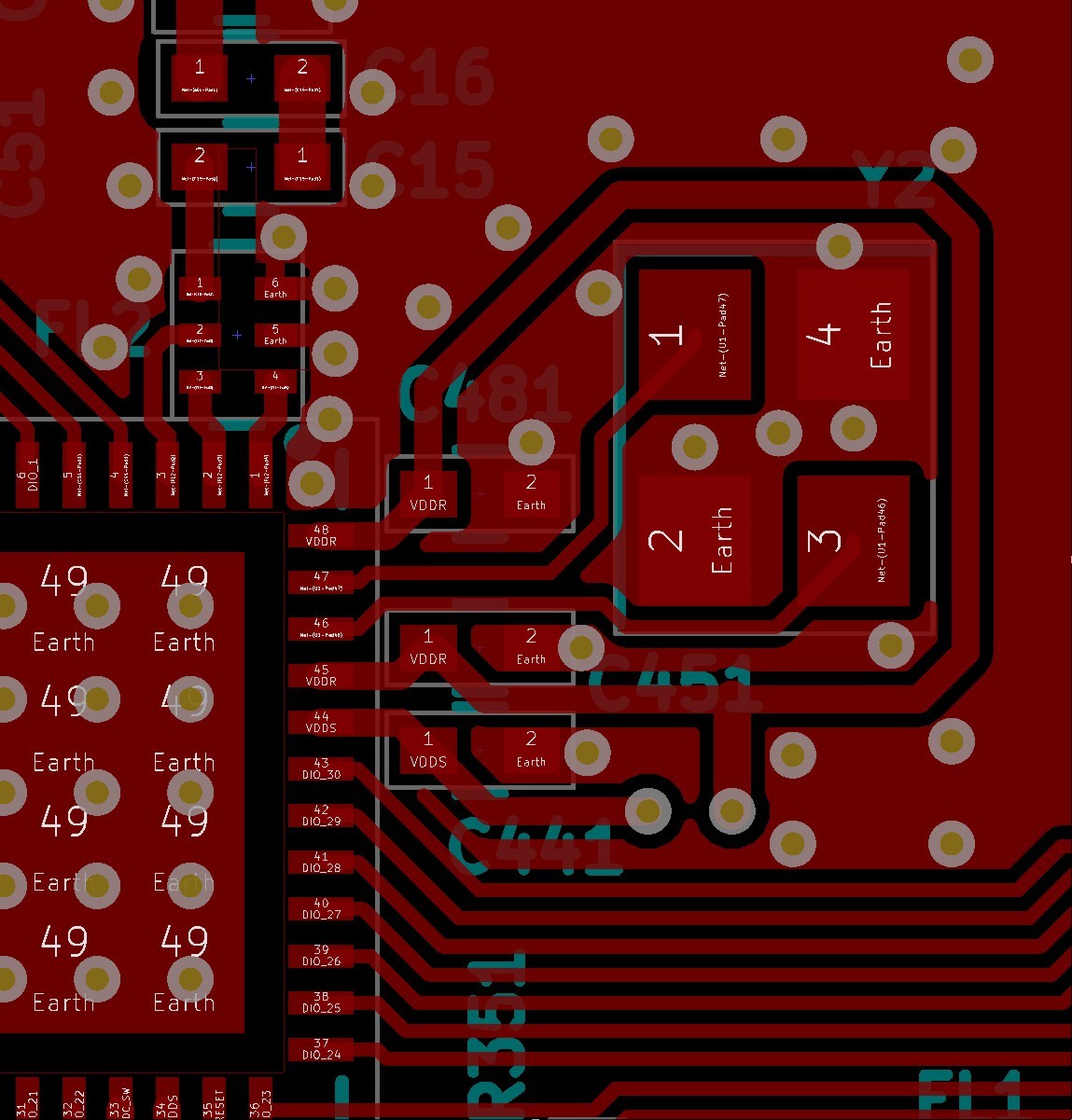

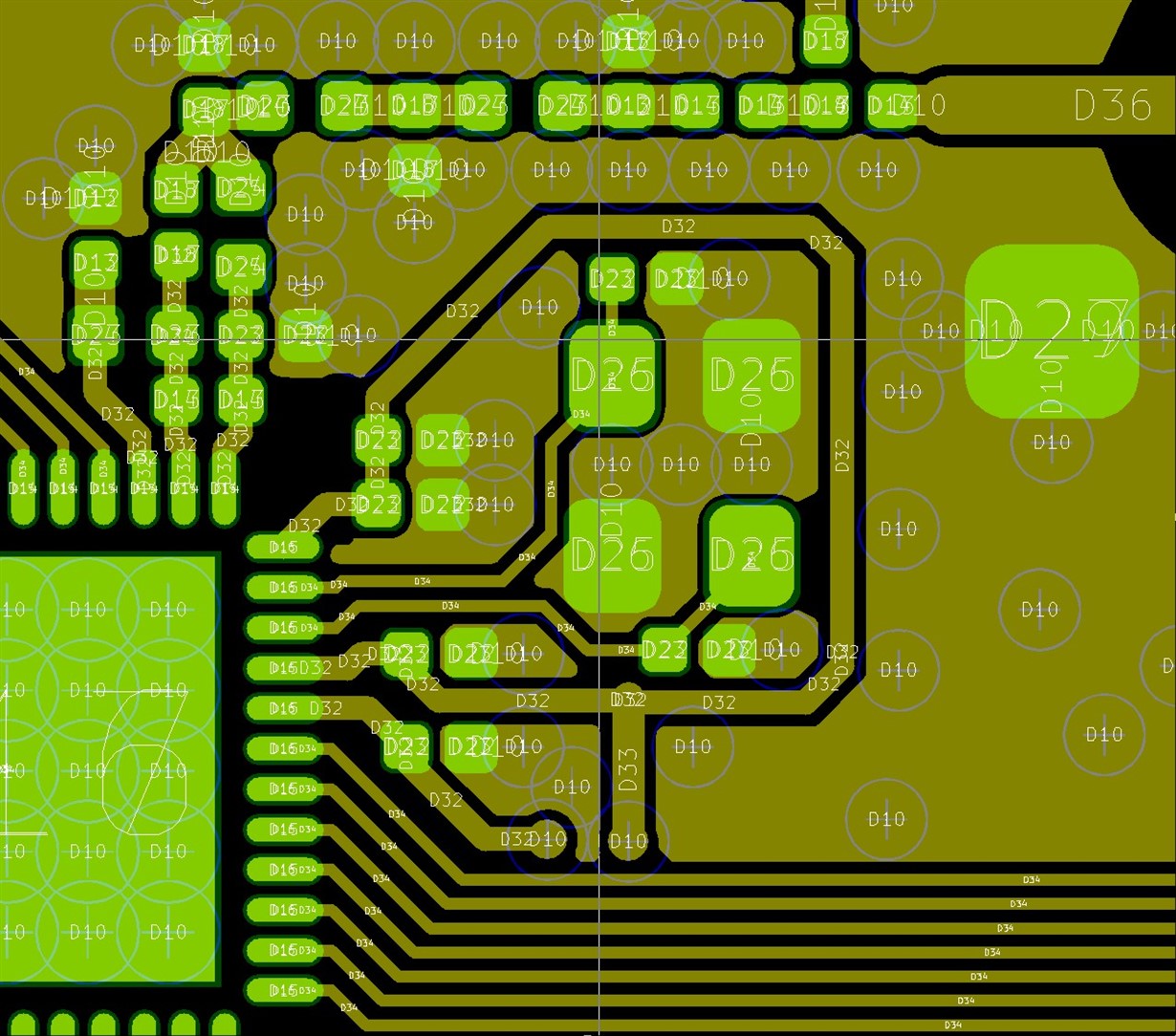

After developing a SW for my project with CCS to test in my CC1310 EVM's on SmartRF06 boards and verifying all worked as intended, I have designed and manufactured a custom board based on the CC1310 2-Layer 7x7 v1.3.3 reference design (CC13xxEM-7XD-7793), but adding the IPC 0850BM14E0016T from Johanson Technology to eliminate passive components and using the PCB antenna. All intended to work in 868MHz.

I loaded the SW in one of my custom board (PCB antenna) verifying it works correctly in debug mode and tried to communicate with one of the EVM board (with the whip antenna). I did this the first because I trusted the tested EVM and I didn't trusted the radio part of my own board, so if something failed I would know it was my custom board. And this is what actually happened: there wasn't any communication between both boards.

I tested every combination between the 2 EVM's versus my 3 custom boards (switching HUB and remote node functions) but nothing worked. I tested directly with my SW and also through SmartRF Studio packet transmission.

I tested again communications between the 2 EVM's themselves: worked as It should.

Then, with no hope (why it should work?), I tried to communicate 2 of my custom boards. Surprise! It worked. My custom boards communicate between themselves but not with the EVM!!!

They did with an RSSI of -40dBm, not the -15dBm of the EVM, but I expected that because the use of a 2 layer board, PCB antennas and the lack of tunned PI netwok.

I am very happy cause my boards work, but the big question is: why they don't work against the EVM's? If I want to put a whip antenna in a new custom design for the HUB to improve the range or simply reduce the consumption, I need to answer that question.

What I first thought was that my custom boards could be transmitting in a different frequency from the planned one due to my design. To tested I used SmartRF Studio in Continuous Tx/Rx mode, changing the frequency and using one custom board and one EVM. Surprisingly I detected -40dBm signal in the 868MHz and only there, with both boards established to that frequency.

So there is no deviation in frequency in my boards. Then, why I can detect a signal with SmartRF Studio in Continuous Tx/Rx mode in 868MHz, but I can't make them communicate through the SmartRf Studio in Packet Tx/Rx mode (nor with my SW) in that or any other frequency? What Continuous mode of SmartRf Studio does transmit and detect?

Thank you very much in advance!

Regards,

Juan Pablo Novo