Other Parts Discussed in Thread: WL1835,

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tapan,

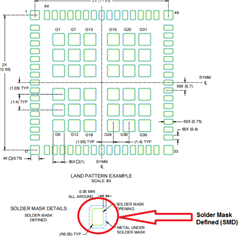

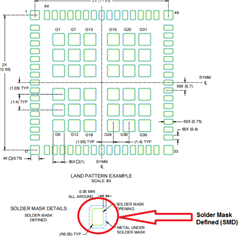

The WL1835MOD is a 0.7mm pitch package. The pad width is 0.4mm and the gap between pads are 0.3mm

NSMD has better solder joint reliability because solder wrap around the PCB pad. Disadvantage is the trace connection to the pad could cause inconsistent solder pad dimension, depends on trace width. A thick trace could cause solder short between trace to pads.

SMD restrict the total exposed solder area. So the dimension of all solder joints are consistent.

Another factor that can cause solder short is component placement. If placement use component thickness, the suggestion is to add 0.05mm to actual component thickness so that the package will sit half way into the paste instead of all the way down.

Putting too much pressure on the solder paste and squeeze them out.

If component placement use force release, the suggestion is to use minimum force which is less than or equal to 3N.

BR,

Seong