Hello

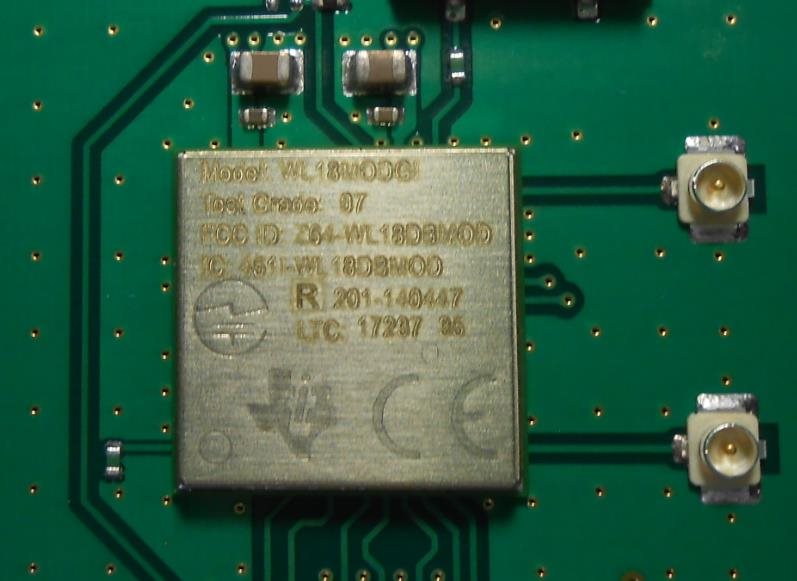

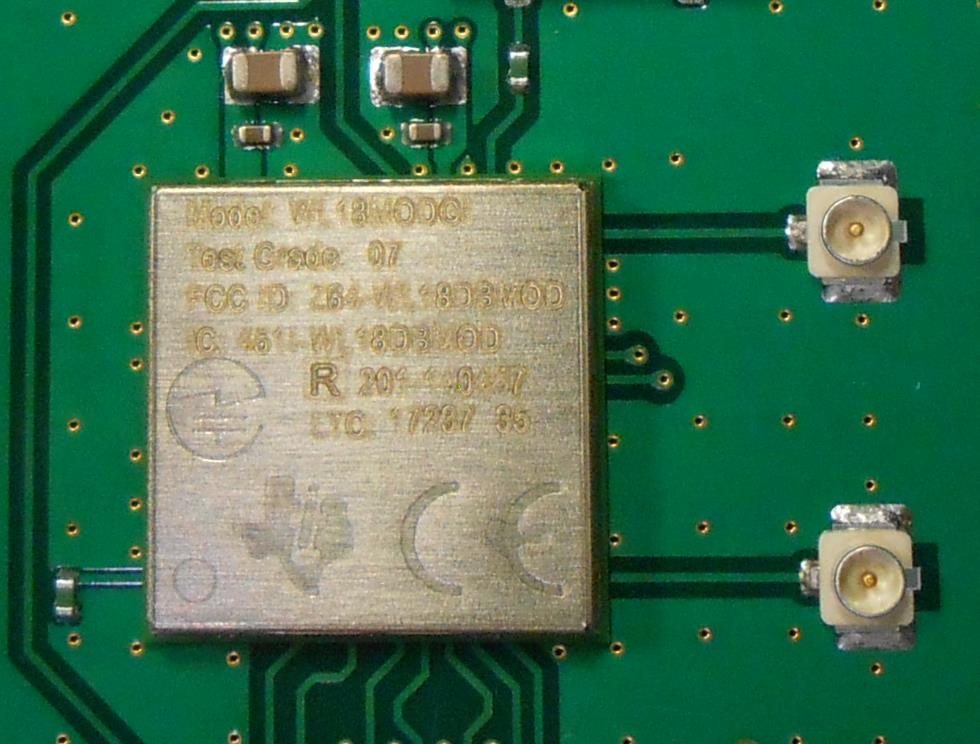

I need you help I need to know the criteria for allowable voids in the pads. We are assuming no more than 30% is this correct. We are using the recommended solder parameters. We used a mole to verify. I am seeing to many voids. We tried N2 and lengthening the soak but either worked. We are using a 5 mil stencil and a 12 zone oven we have SPI. Can you help us with any process improvements we do not want to put good parts in the land fill.