Other Parts Discussed in Thread: CC3220SF, CC3220MOD, TPS62160

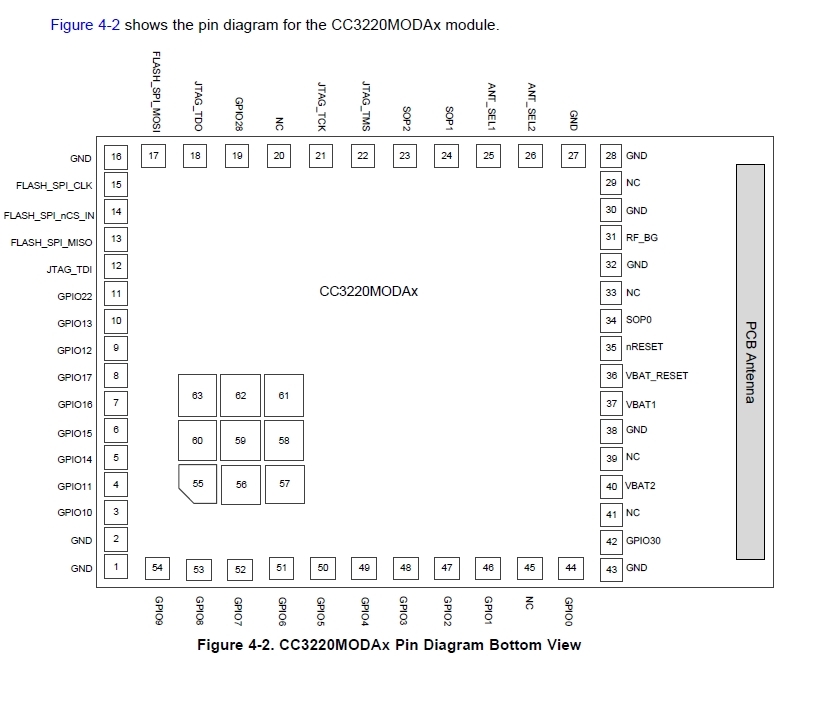

We developed our custom board(cc3220modasf) time being we attached only module.

CC3220 Launched pad(3.3v) connected to our custom board power supply.

Our custom board working fine i can able to debug and flash but module heating after some time module is off automatically after power off and power on power working fine.

why module is heading ?

Vasu