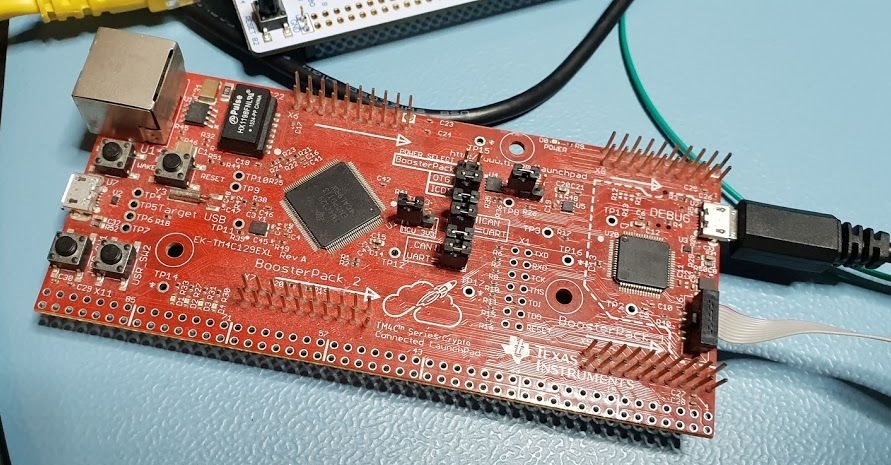

Other Parts Discussed in Thread: EK-TM4C129EXL

Hi sir,

I have a doubt,

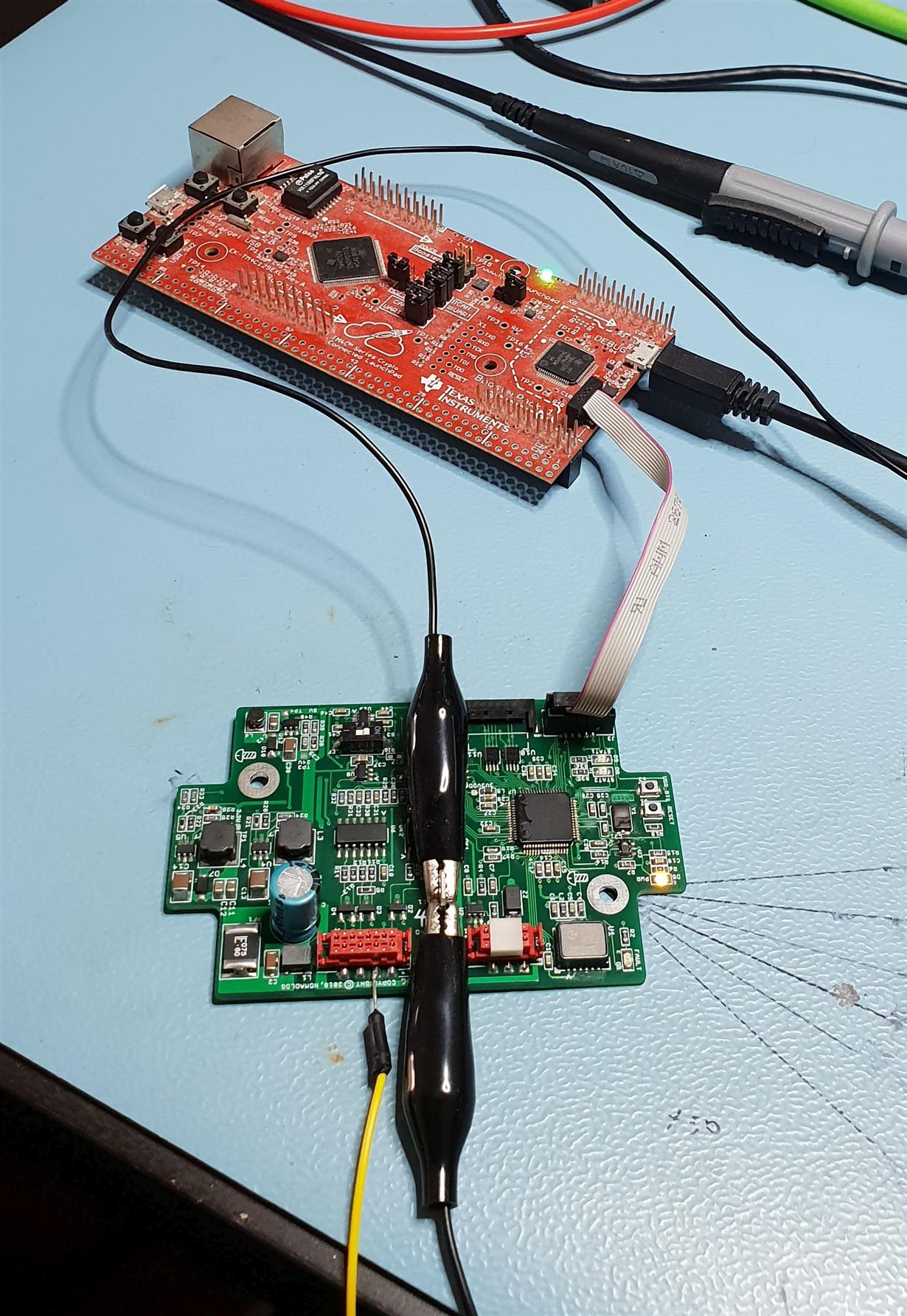

1. I am using my development board of EX-TM4C129XL as a debugger. So i am going to remove the resistor are R6, R7, R8, R10, R11, R15, R16.Whether it is correct or not?

2. I need JTAG female connector interface with my custom board.but I didnt find it digikey. Please help me to solve this problem (10 pin 1.27mm pitch)