Other Parts Discussed in Thread: DRV2700

Good morning.

I'm Dae Young Lee in Microsystems Laboratory of Myongji University(from south korea).

We are writing to you for advice on the problems faced in using the T.I.'s DRV2700EVM-HV500 (hereinafter 'evaluation kit') products.

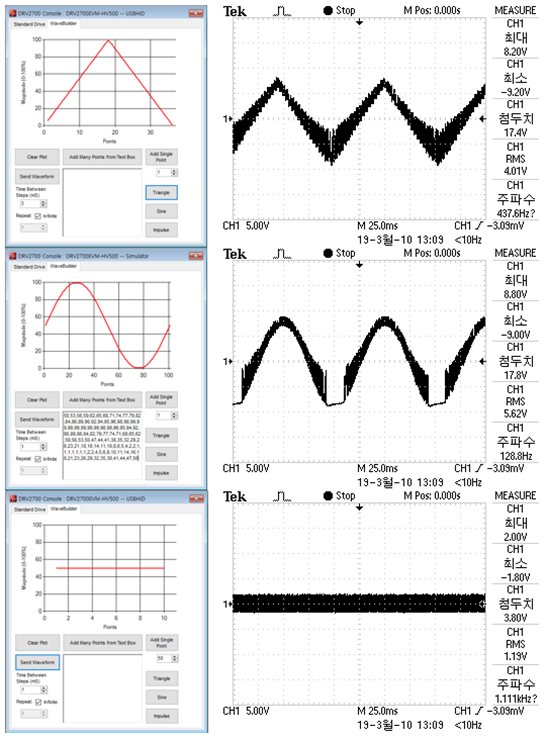

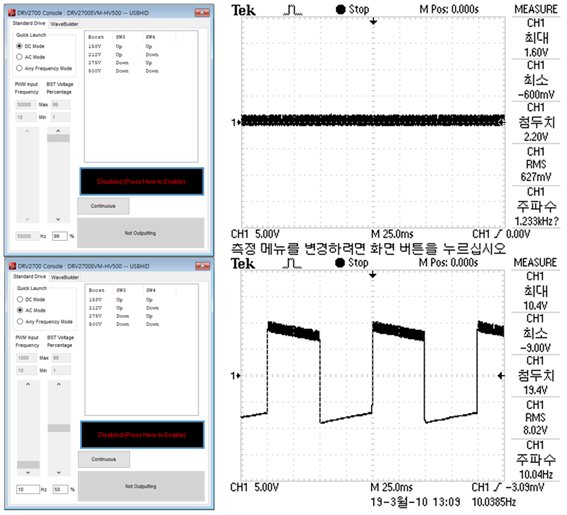

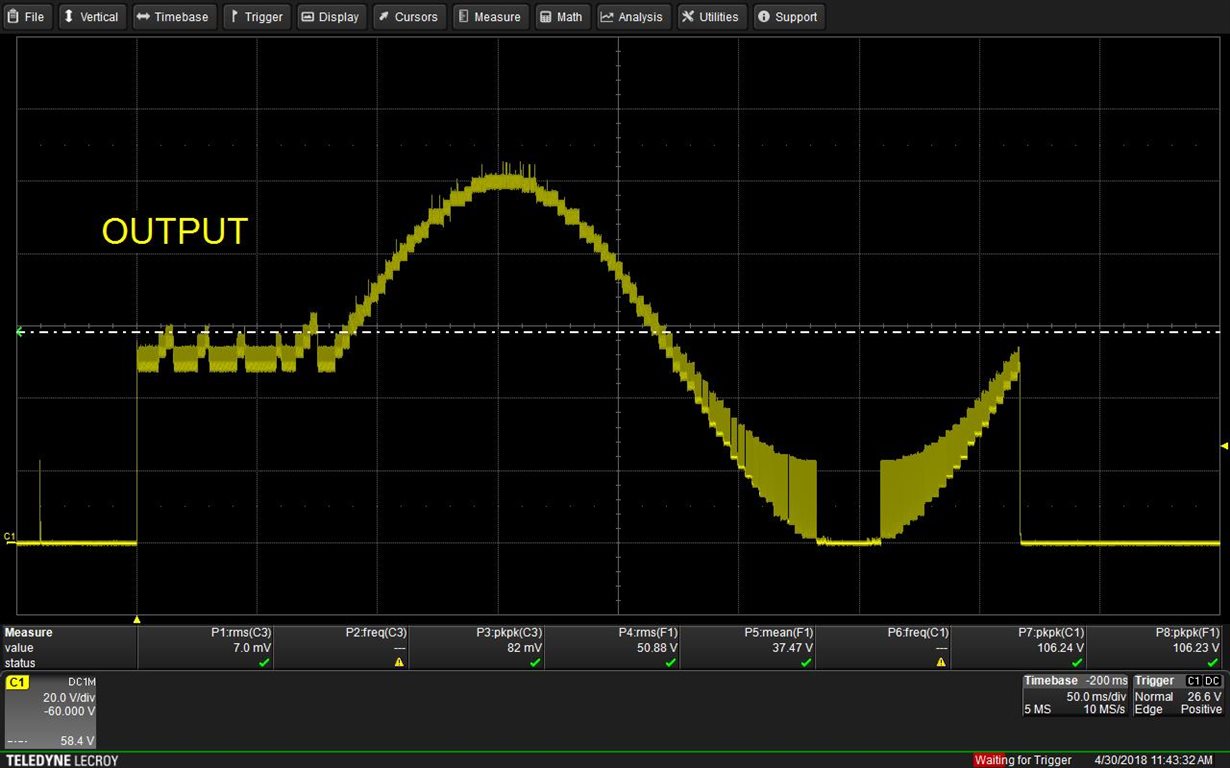

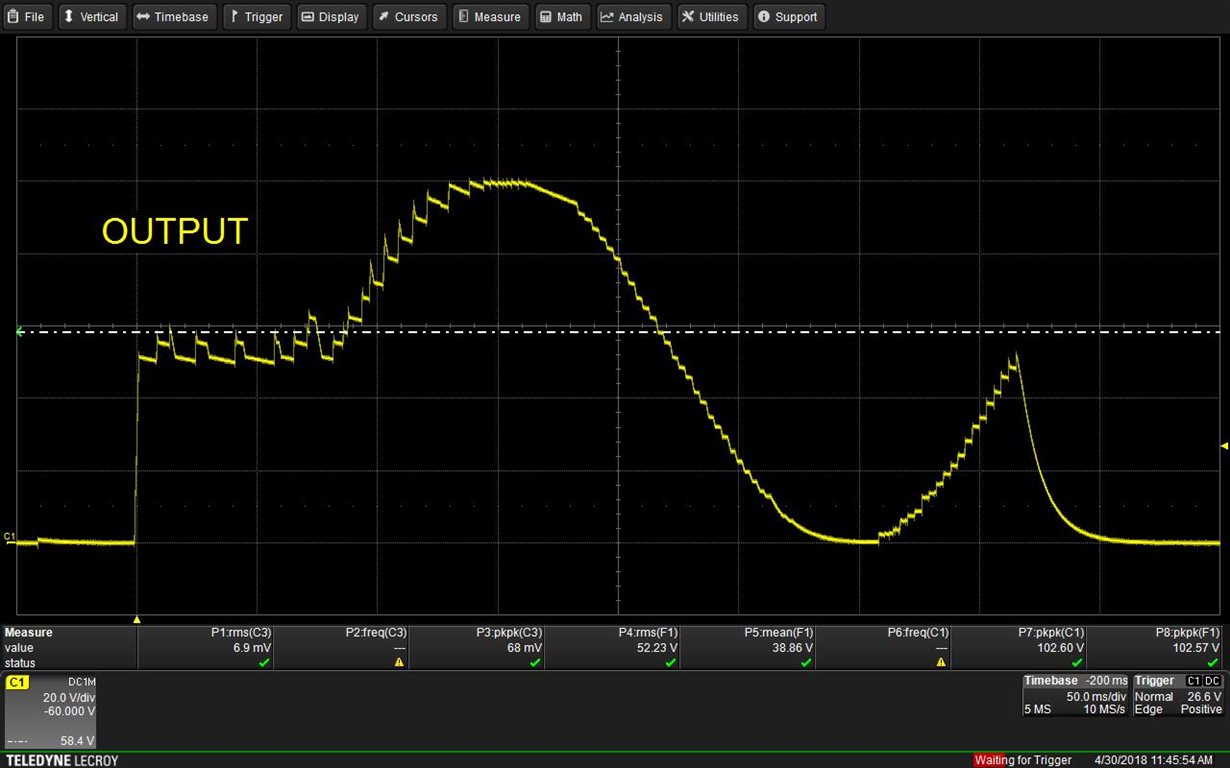

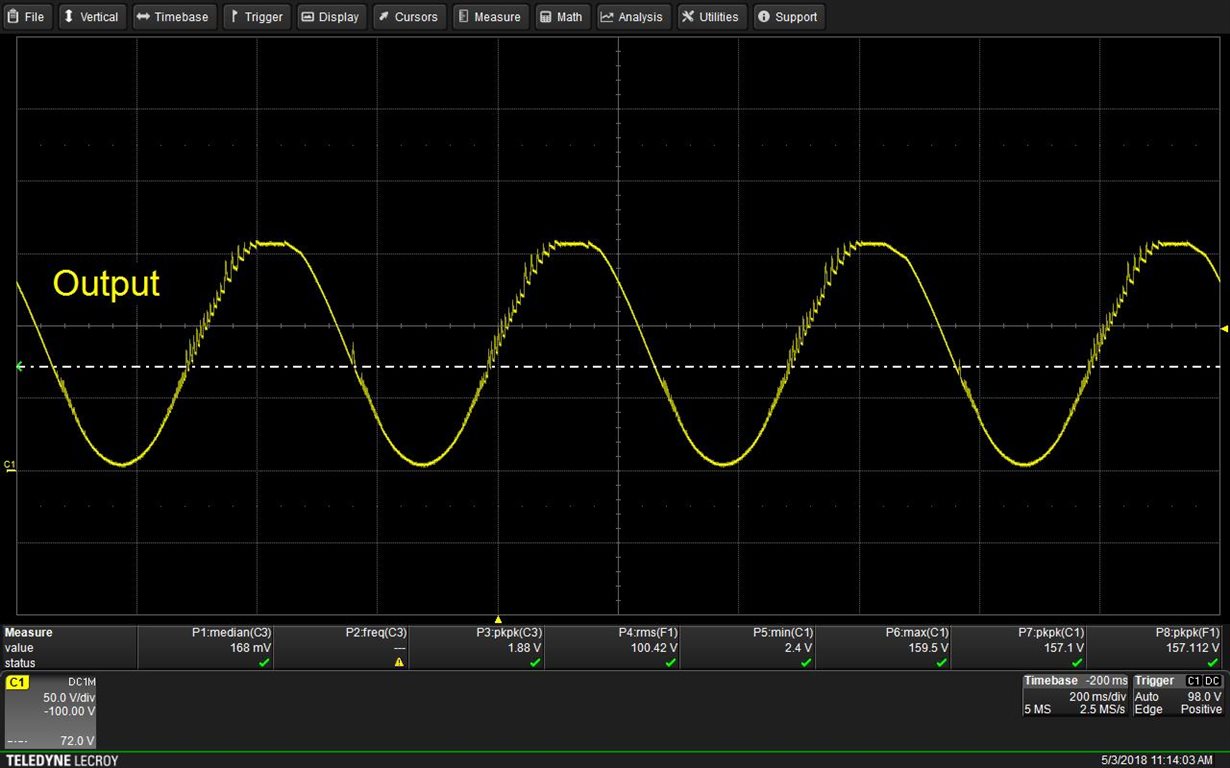

The goal is to output signals of various types (sine wave, square wave, DC) using the evaluation kit.

It was possible to output various types of signals by using the evaluation tool of the evaluation kit (Piezo Control Console).

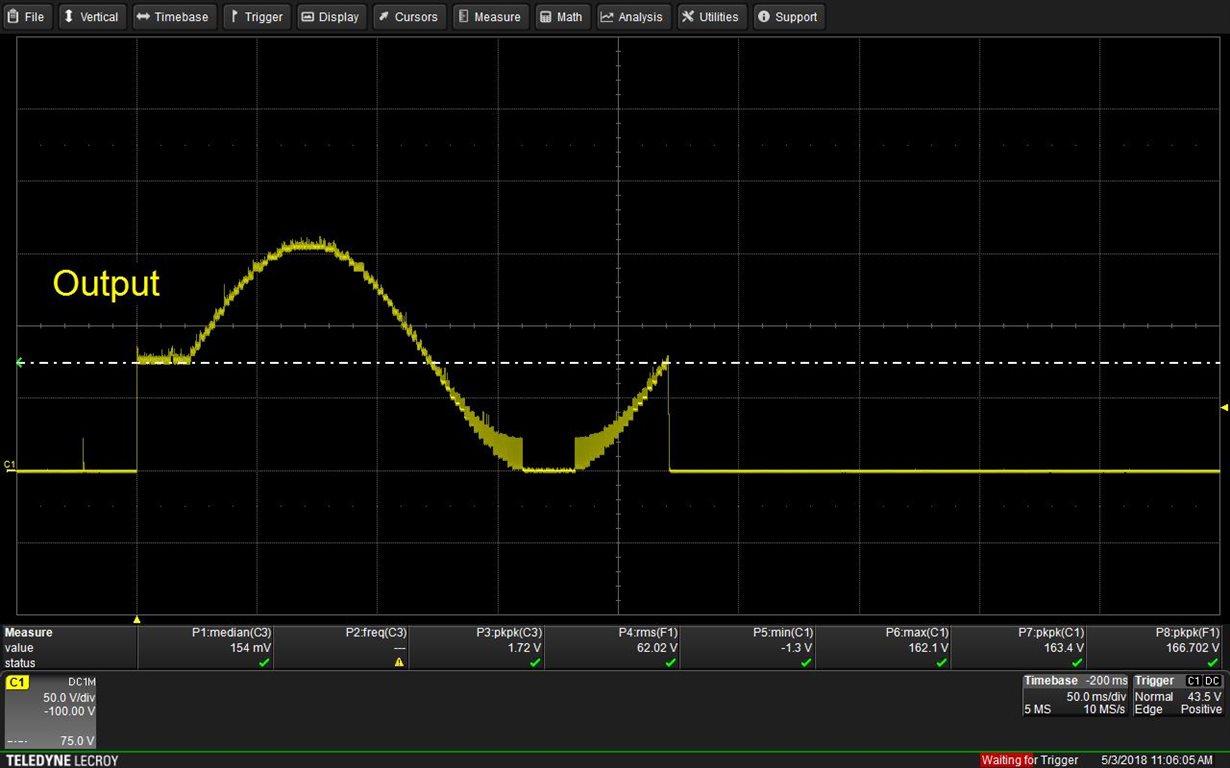

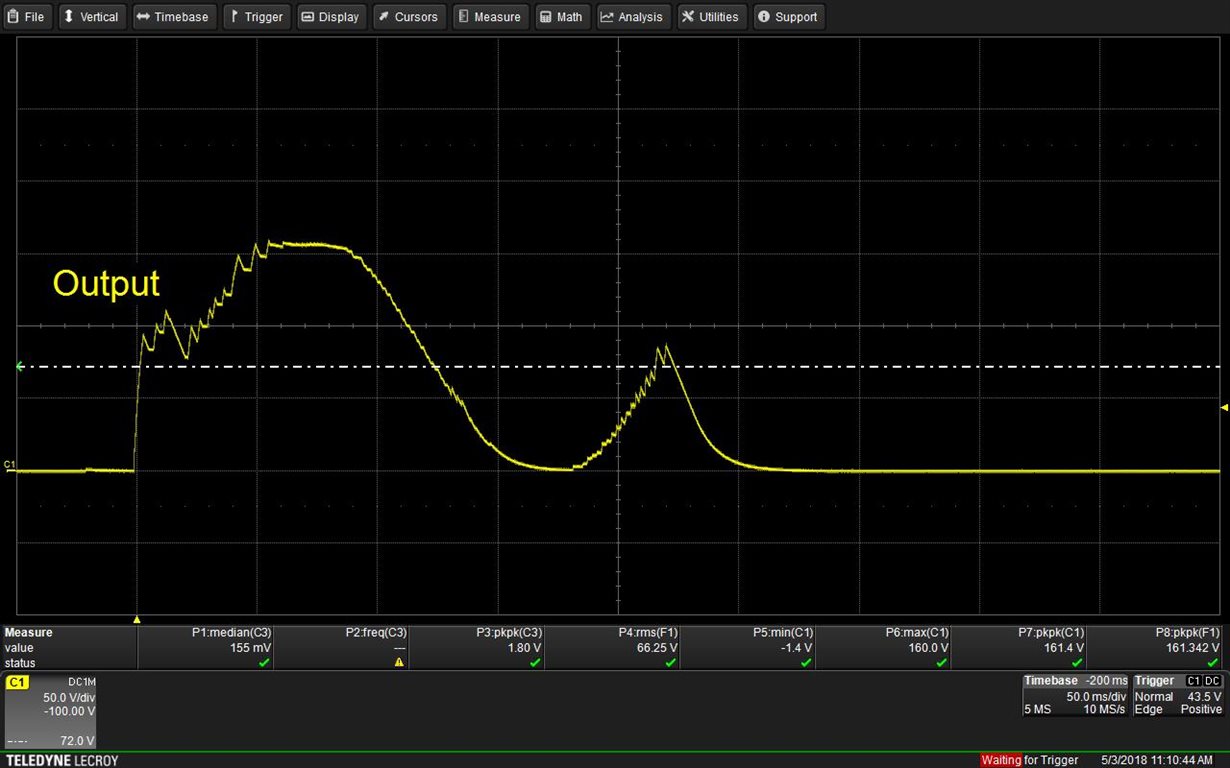

However, the noise is too severe to function properly.

(At the time of signal output, the setting screen of the programming tool and the shape and information of the output signal are attached to the file.)

Please check if the output information of the evaluation kit belongs to the normal category through the output signal of the attached file.

If this is a normal category, please advise how to solve the problem you are experiencing (serious noise).

- The environment using the evaluation kit is as follows.

: Operating system - window 7, window 10

: Power source - USB (2.0, 3.0 port)

: Setting voltage - 158 V (x 1/10 magnification at the time of measurement)

: Oscilloscope - Tektronix 'TDS1012B'

Ø Inquiry summary

- Goal: Various signal output using evaluation kit

- Problem: Output of sine wave, square wave etc. is possible, but it does not function due to serious noise.

- Content: Check whether the evaluation kit in use is working properly, how to attenuate noise during signal output