In my first post, I talked about the need for modular, flexible and smart design in analog output modules and explored methods for improving efficiency in a typical high-side voltage-to-current converter used to drive 4-20mA outputs. Figure 1 shows an implementation that involves a buck/boost converter in a simple feedback network to supply just the necessary power to the load. While this implementation makes 4-20mA generation highly efficient and thermally optimized, it comes with a reduced settling time. So in this post, I will explore how to balance efficiency without sacrificing settling time.

Figure 1: High-side voltage-to-current converter with a buck/boost converter

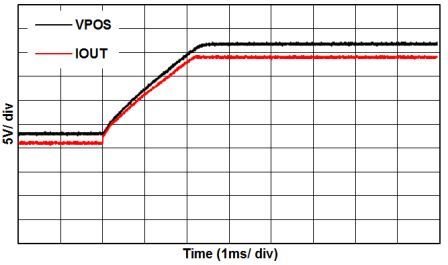

As an example, let’s assume a load of 1kΩ. If the digital-to-analog converter (DAC) code changes from a 4mA output to a full-scale 24mA output, the buck/boost converter will boost from approximately 7V to 27V, as the system is fully adaptive. Since the buck/boost converter needs to charge the large storage capacitor, the settling time of the system could be as large as a couple of milliseconds, as shown in Figure 2. In such a fully adaptive system, the settling time is completely dominated by the buck/boost converter. However, some systems need to have a relatively faster settling time while still meeting efficiency requirements.

Figure 2: Settling time for a fully adaptive system

You can meet this goal using TI’s DAC8775, a quad-channel 16-bit 4-20mA DAC with adaptive power management. This DAC integrates an analog-to-digital converter (ADC) to sense the load and set the buck/boost converter to a fixed value.

The block labeled “Auto Learn” in Figure 3 is a high-level representation of this system. Based on the ADC’s calculation, the buck/boost converter clamps to a fixed value, which satisfies compliance for a full-scale output current at a given load. Once the DAC code written exceeds quarter scale, auto-learn mode kicks in, starts calculating the load in the background, and sends the information to the buck/boost converter to adjust its value. This results in the buck/boost converter clamping the supply to the value needed to support the maximum current for the given load. The settling time of the system then becomes dominated by the DAC which is typically more than an order of magnitude faster than the buck/boost settling.

Figure 3: The DAC8775’s integrated ADC senses the load

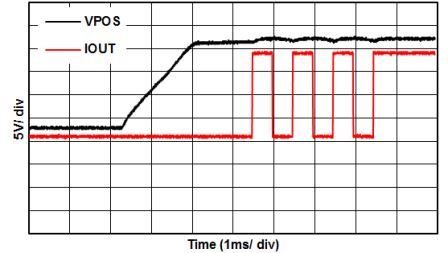

Back to our example 1kΩ load: once enabled, auto learn will calculate the load as 1kΩ and set the buck/boost converter to 27V. This achieves the maximum power saving without sacrificing settling time. As you can see in Figure 4, after the buck/boost output settles, all of the consecutive DAC code updates settle within 10µs. This is a significant improvement in settling time.

Figure 4: Setting time with auto-learn mode

Another advantage of such an implementation is that it makes modules more flexible. System designers don’t need to spend engineering time to optimize modules for different loads. This implementation enables the system to “learn” the load automatically and adjust the configuration as necessary. In addition, because auto-learn mode runs in the background, it saves costs during installation.

We will continue to cover topics around trends in factory automation in subsequent blogs. Until then, learn more by checking out TI’s broad precision DAC portfolio or the DAC8775.To get posts like this delivered to your inbox, sign in and subscribe to Precision Hub.

Additional resources

- Download the DAC8775 data sheet.

- Evaluate the DAC8775 with the DAC8775 evaluation module.

- Download these reference designs:

- Watch this video about DAC8775 features and uses.