Hi TI forums!

We've come across a hiccup while testing some of our newly designed boards.

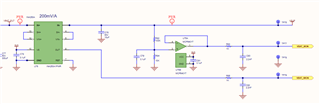

Initially we thought it was a FW error when our current readings were not exactly as expected. However on one of our designs we have two of these current sense IC's in series. (The references are not tied together)

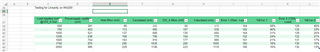

With both ICs were giving different results, it lead us to run some tests and below you can see each IC has set mV offset from the expected reading.

Column D is the expected Reading. Column F and H are what we're getting.

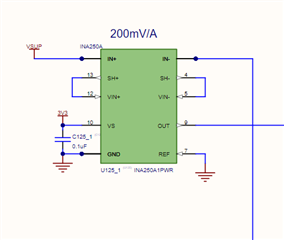

We also tested another INA250A1PWR, not shown in this screenshot, that one was getting within 5% of the expected readings. So it is not an issue with the PCB. (Measurements are taken right off pin 9 of IC)

If the ICs are swapped locations on the board the readings follow the IC not board location.

Any suggestions on where the issue may lie, or do we have a bad batch of parts?

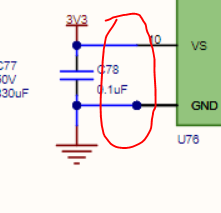

Schem snippets

Thank you for your time!