Other Parts Discussed in Thread: LMH6552,

Hi team,

I have a application details want to confirm wiith you while using LMH6518+LMH6552 as the DSO signal chain.

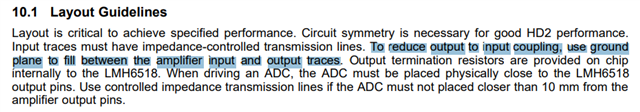

what should I do with the GND cooper in the system, if I just solder the cooper all over the whole signal chain will be better for sheilding or leave the LMG6518 and LMH6552 placement section no GND cooper?

Could you please give some recommendation here?

Thanks

Best regards

Mia Ma