Other Parts Discussed in Thread: TINA-TI, OPA340, MAX660, TL7660, LM317, OPA2340, LM337

Hi Team,

I am a Diesel mechanic and while I have basic auto electrical and electronics understanding I don’t have the ability to design my own component in this instance and wondered if you may be able to help or point me in the right direction. I need a digital to analogue converter for a project I am currently working and need something that is assembled and programmed ready to connect, is this something you could provide? I understand you may need more information but I’ll do my best to describe what I am after. I am needing a DAC to convert the signal from 2 separate speed sensors form a 0.65v- 1.325 square wave digital signal to an analogue A/C sine wave signal that I have measured to be 5v peak to peak with the shaft speed at 190rpm and it needs to read between 0 and 1000 rpm. The pulse wheel on the shafts has 48 pulses per revolution. Obviously, the amplitude varies relative to speed of the shafts. The system voltage is 12 volts. I’d greatly appreciate any information you can provide.

Unfortunately I can't get any manufacturer data regarding the sensor or the module receiving the signal as such, only what I can measure. What this is is a Toyota rear axle that I am swapping out of a later model Toyota that has a much stronger final drive. The new axle has the digital 2 wire wheel speed sensors and the vehicle I am fitting it to requires the A/C signal, the signal is sent to the ABS module in the vehicle. Toyota don't supply any information on their equipment other than what is required to diagnose faults. I could as a last resort modify the axle to take the analogue wheel speed sensors and the pulse wheel to suit, however I'd like to avoid this if possible so as readily available part will still fit if required.

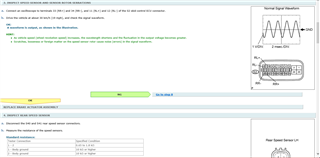

This is the only information I have regarding what the signal should look like, this comes from the diagnostic manual of the vehicle that I am upgrading the axle in.

I wondered if this would work https://www.ti.com/lit/ds/snosbi2c/snosbi2c.pdf

Is it even possible to convert a digital speed signal to an analogue signal.

I don't think that if the amplitude of the analogue signal didn't vary with the change in frequency would be a problem.

Best Regards,

Tom

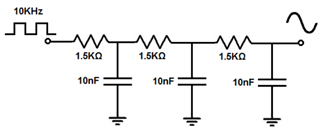

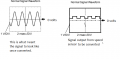

I am not sure I have been clear in what I want to achieve, I hope this crude image will give more clarification. Kai the LM2907 you suggested looks to me like it is designed to receive a signal from an inductive type sensor where as I have a signal from a hall effect sensor generating a DC square wave high/low signal and I want to convert it to an A/C signal.

I am not sure I have been clear in what I want to achieve, I hope this crude image will give more clarification. Kai the LM2907 you suggested looks to me like it is designed to receive a signal from an inductive type sensor where as I have a signal from a hall effect sensor generating a DC square wave high/low signal and I want to convert it to an A/C signal.