- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

We are using in the design that is in production this part: LM2902KAVQPWRQ1.

Now there is not clear for me PCN 20241119002.2 .

It says "anticipated impact on fit, form..." so there is not clear now whether there is a change or not?

In other place of PCN there is a table stating the part is already Automotive Qualified, so that means all tests of new part are done, right?

And second some general question as I am not an expert in microelectronics: Despite changes like wafer size change, die change, process change, bond wire change we can still have same electrical parameters (like switching, ratings, thermal)? So any single parameter from datasheet is not changed with all those changes in manufacturing process?

The part number is not LM2902KAV but LM2902-Q1.

The guaranteed datasheet limits have not changed, but typical values might have changed. The new die is that of the LM2902BA-Q1; you could just as well order the LM2902BAQPWRQ1.

Hi Adam,

In other place of PCN there is a table stating the part is already Automotive Qualified, so that means all tests of new part are done, right?

As Clemens indicated, LM2902-Q1 is automotive grade op amp (-Q1 refers to AEC-Q100 or AEC-Q101 qualified). Here is the PCN link.

https://www.mouser.com/PCN/Texas_Instruments_PCN_20241119002_2_Change_Notification_NCC.pdf

Despite changes like wafer size change, die change, process change, bond wire change we can still have same electrical parameters (like switching, ratings, thermal)? So any single parameter from datasheet is not changed with all those changes in manufacturing process?

Yes, the performance and datasheet limits and package size etc. will remain unchanged. If you are concerned about the changes, you may request the samples and check it out.

If you have other questions, please let us know.

Best,

Raymond

Thanks for an answer.

I have one more question regarding safety/reliability topic:

This part probably had some failure rate, was safety analyzed etc... after PCN does any safety measure changed? For aexample FIT rate or any other safety measure. Im not safety or FMEA expert but would like to know if I can assume in this case safety topic need to be considered and revised after PCN or its not an issue at all. If yes where I can find any safety (fmea, fit) analysis of this part, or maybe you do not provide it?

Also in general could you adivce:

1. Wafer change does change the safety/reliability parameters or not?

2. Die change does change the safety/reliability parameters or not?

3. If stated in PCN - "no change in fit, form, function" - does it mean also that safety/reliability paramteres does not change?

Hi Adam,

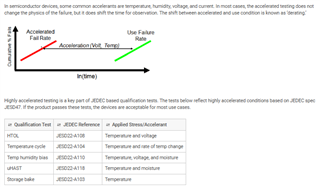

RFAB Process Qualification (JEDEC Standards) is not new, which the process has gone through years of development. It has to go through Accelerated Life Testing, Defect and Yield Analysis, Electrical and Functional Reliability, Reliability Monitoring and automotive qualification verification and validation process etc..

Here is an example of Accelerated Life Testing process, where you are able to find TI's quality & reliability information and data on our product below.

https://www.ti.com/support-quality/reliability/reliability-testing.html

Like any other IC products, quality and reliability figures in semiconductor processes are derived from known testing data collected during development, validation, and production stages. This data provides statistical insights into the performance, durability, and failure rates of devices under various conditions. Theses processes and figures are generated and validated in real-world performance and statistically.

I am not able to answer all your questions, but this is how any semiconductor processes and reliability data are evaluated, including automotive, military, aerospace and space products etc.

If you have other questions, please let us know.

Best,

Raymond