- Ask a related questionWhat is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Tool/software:

Dear e2e Support,

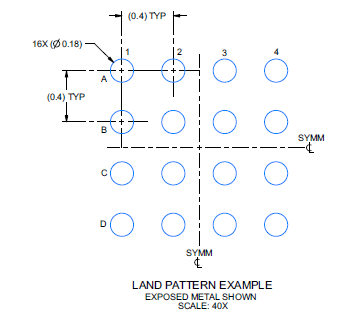

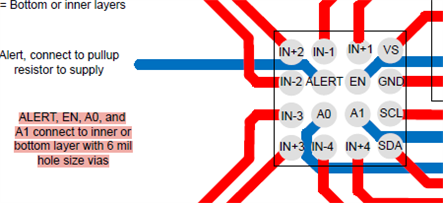

In order to comply to my customer industrialisation constraints, we are wondering if a 0.25mm is acceptable, vs the 0.18mm recommended; at least for the Alert, EN, A0 and A1 pins which require via-in-pads.

Is there any risk to avoid?

Regards,

Hi,

Here are my responses to your questions:

In order to comply to my customer industrialisation constraints, we are wondering if a 0.25mm is acceptable, vs the 0.18mm recommended;

This isn't an ideal solution, our EVM has 6mil vias with 1 mil (0.0254) solder extension to give a total of 8mil (0.2032mm) pads on the Alert, EN, A0 and A1 pins. The others have the recommended 0.18mm solder extensions.

A 0.25mm spacing will but the Alert, EN, A0 and A1 pins close to the bus pins, this may or may not work depending on the customer's voltage thresholds and interreference tolerance.

I wouldn't recommend a 0.25mm solder extension, the maximum I'd suggest is 0.2mm.

Best,

Mallika Senthil