Other Parts Discussed in Thread: REF200

Tool/software:

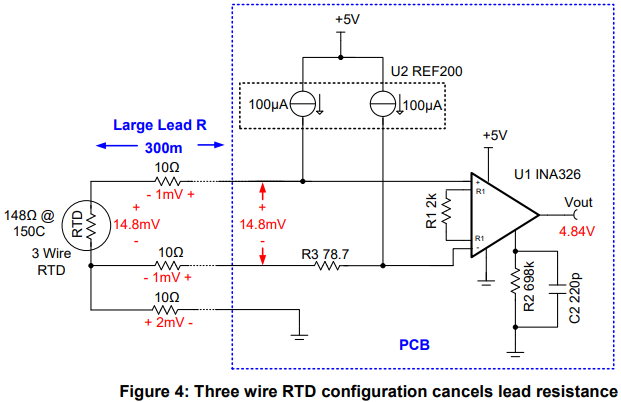

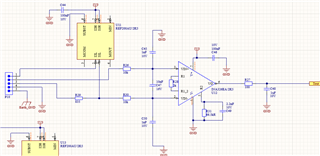

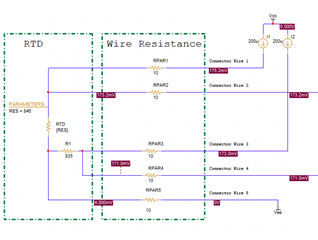

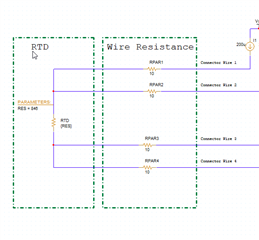

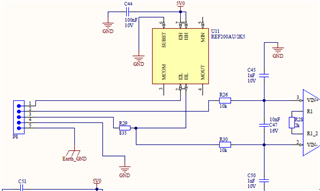

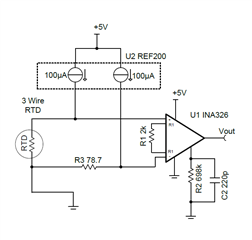

In the document “RTD to Voltage Reference Design Using Instrumentation Amplifier and Current Reference”, the above 3-wire PT1000 connection is made.

How can I make a 4-wire PT1000 connection with the same component (Ref200 and Ina326) and the same design?