Other Parts Discussed in Thread: OPA177, OPA4205, OPA4277, OPA4206, OPA4202, INA188, OPA202

Tool/software:

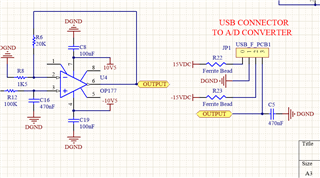

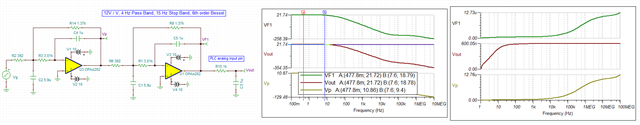

I am using an analog amplifier circuit using OP177GPZ for more than 15 years. Recently I have switch to OPA4180 instead of OP177. But I face two different problem. Circuit schematic is same except OP177 and OPA4180.

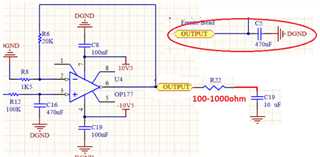

1-) Output swings compared to OP177 when I test same loadcell and setup board with OPA4180. I have a test setup that I test my boards. On my test setup this swing is not that noticeable. But when I connect my board to the machine this swing becomes noticeable. Only difference between test setup and machine is cable lengths I think. output of OPA4180 is connected to PLC module. In test setup cable length is shorter. both from loadcell to amplifier board and from amplifier board to PLC module. Swing has very slow frequency. approximately 1-2 minutes. And voltage change approximately 2-3mV peak to peak.

2-) Depend on how power connector is plugged on the board output of OPA4180 changes. My power connector has +15v, -15V, GND and analog output pins. It is a 3.5mm pluggable pcb terminal. While plugging the connector if +15V rail and -15V rail makes contact in different order output becomes maximum possible positive output. no matter I apply signal on input of opa4180 output does not change. when I re-plug connector then it starts to operate correctly.

Does anyone has an idea about these observations.

Thanks.