hello

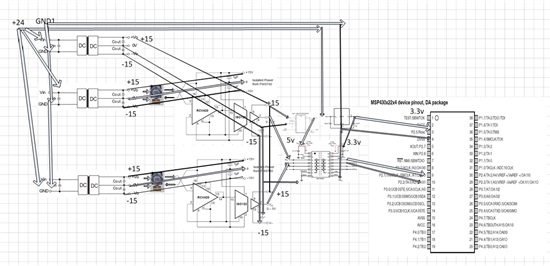

I'm developing a PLC with 3 inputs loop current (4-20 mA) for industrial use.

It has 3 modules interconnected by wirlesshart controlled by msp430.

My intention is to use a multiplexer for that purpose.

SN65HVS880

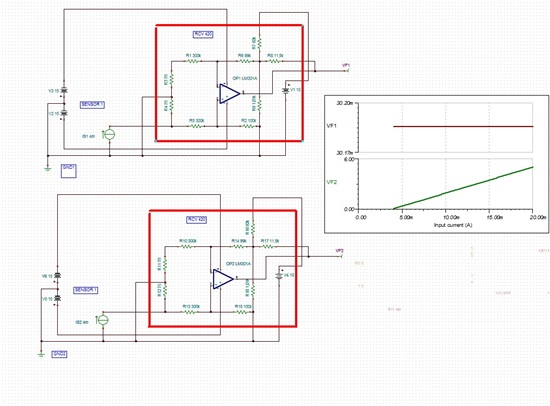

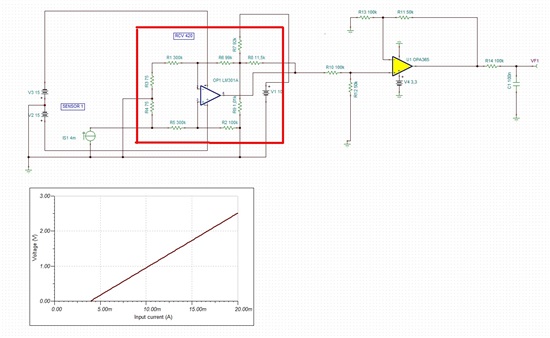

the loop current measure connected sensor by RCV420

Is correct use of these components?

Thanks & Regards,