Other Parts Discussed in Thread: DRV594, DRV595, DRV593, OPA2192

Hello,

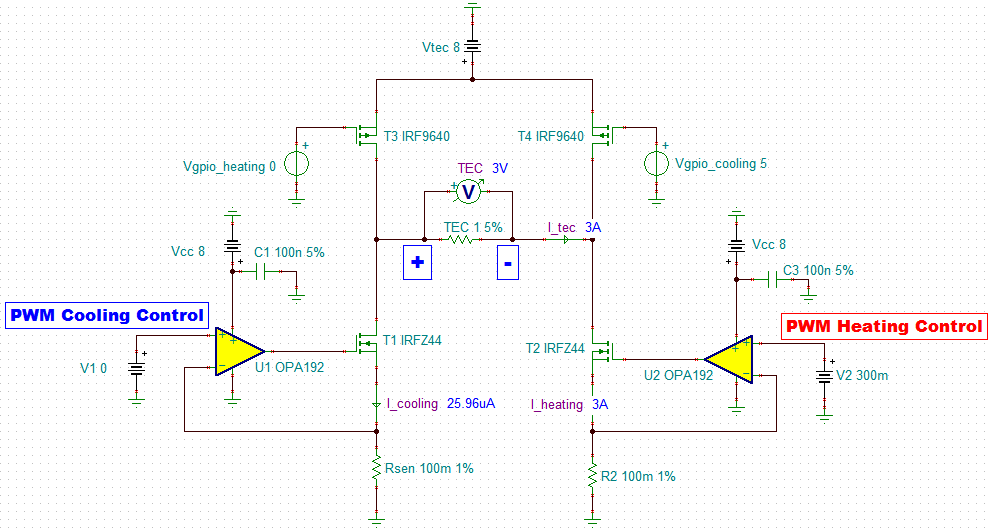

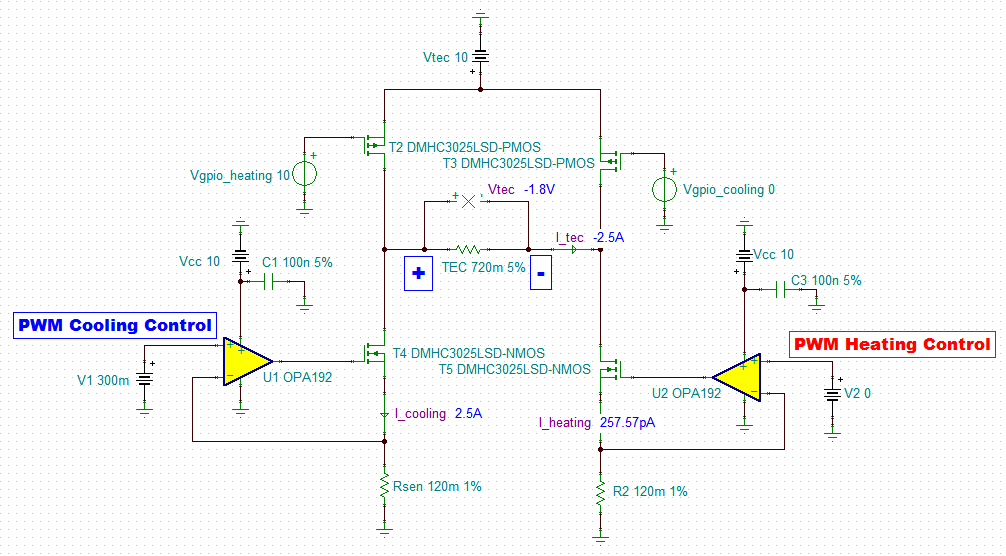

Our customer is looking for H bridge TEC driver amplifier driving at least 3A, 3V+/-1.8V output voltage from 200Hz 0V to 3.3V PWM input. I am not sure if LMH6526 can support this application however, could you help our customer if LMH6526 or other device meets with his requirement.

best regards,