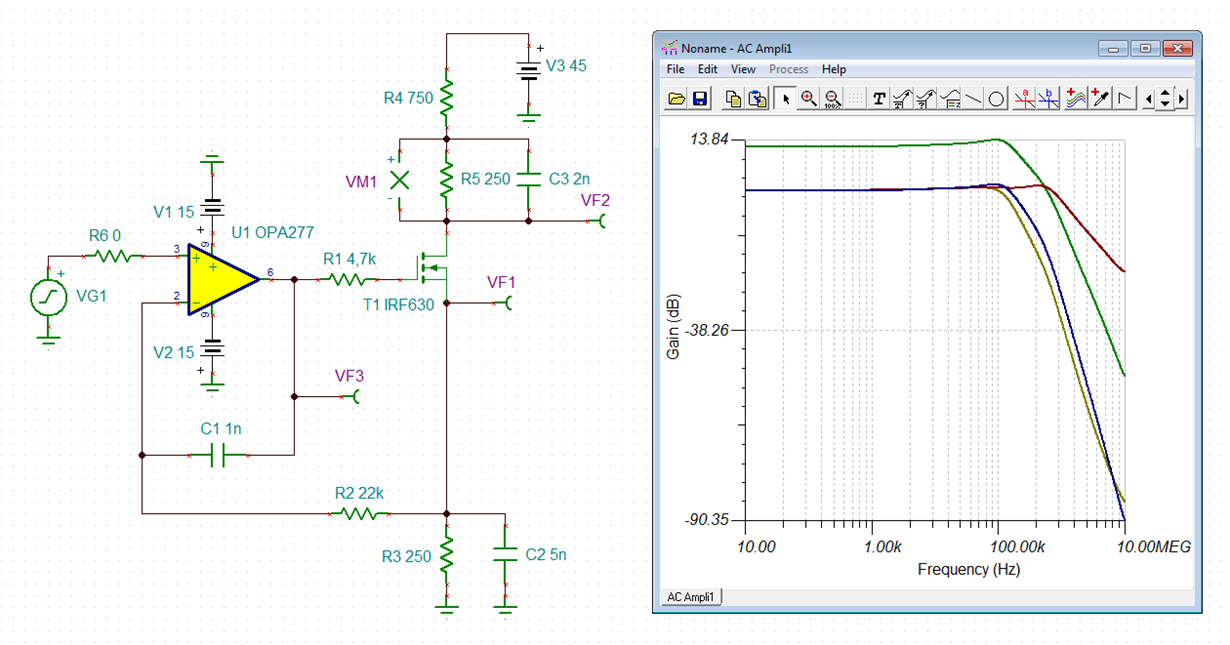

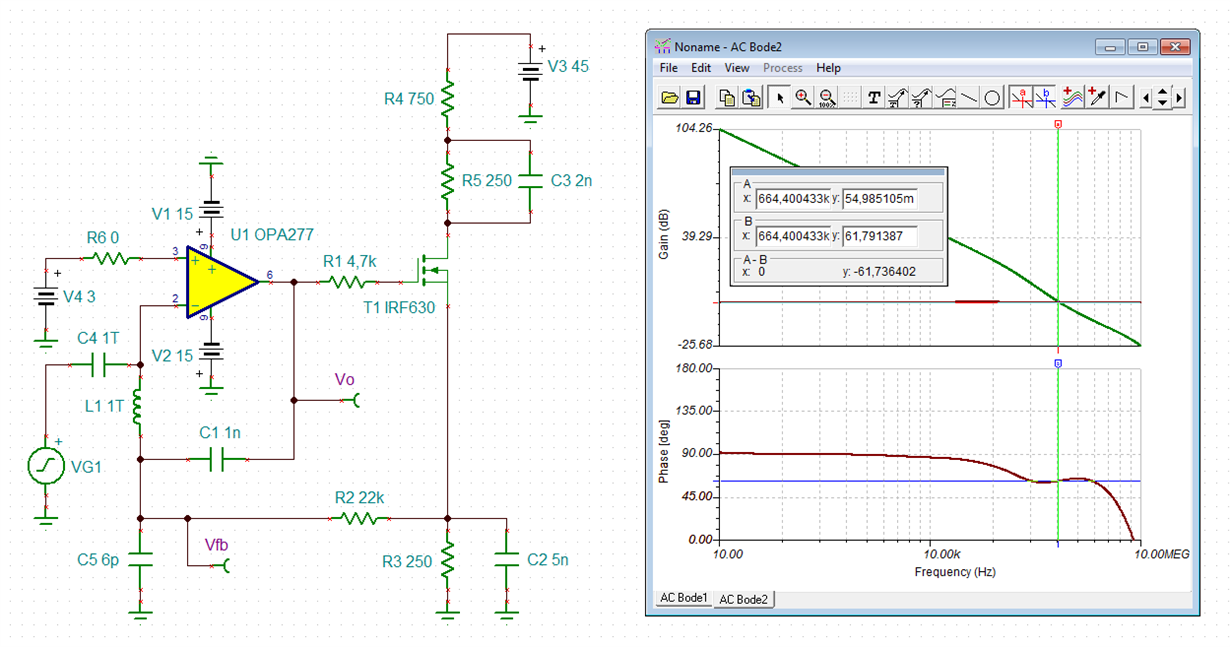

Other Parts Discussed in Thread: TINA-TI

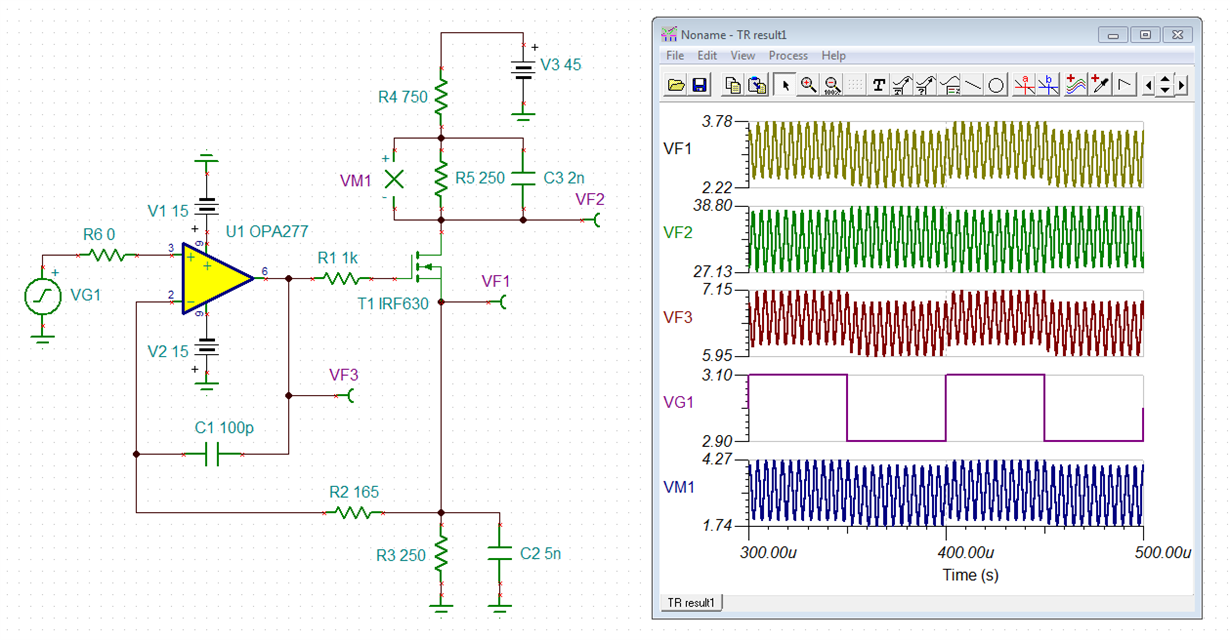

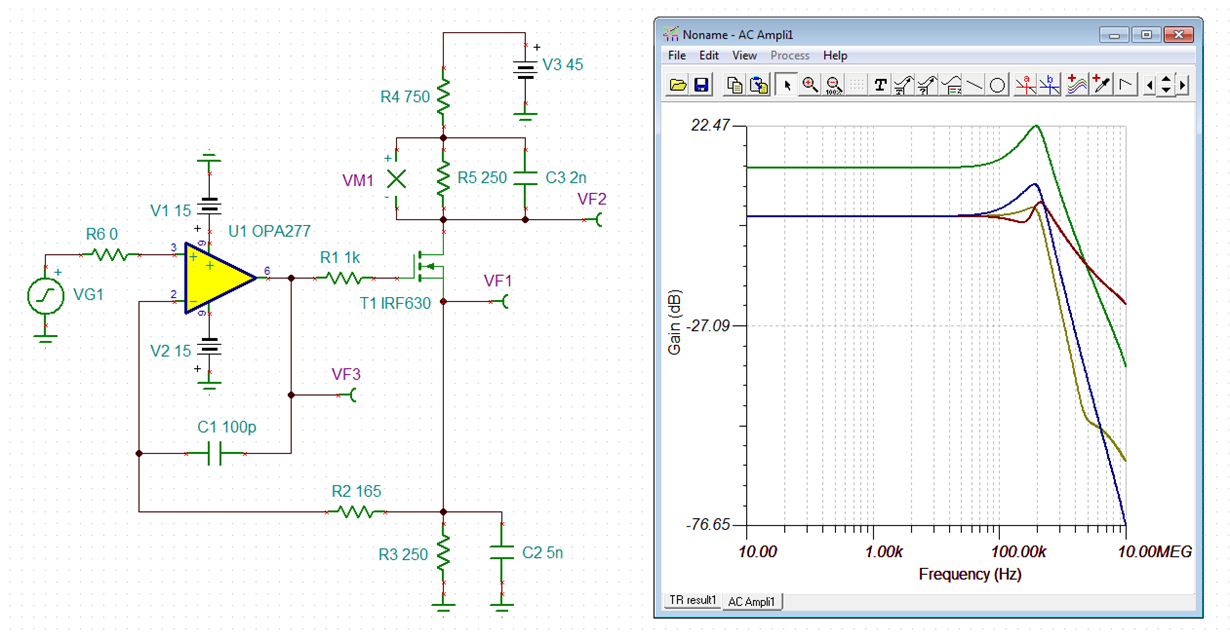

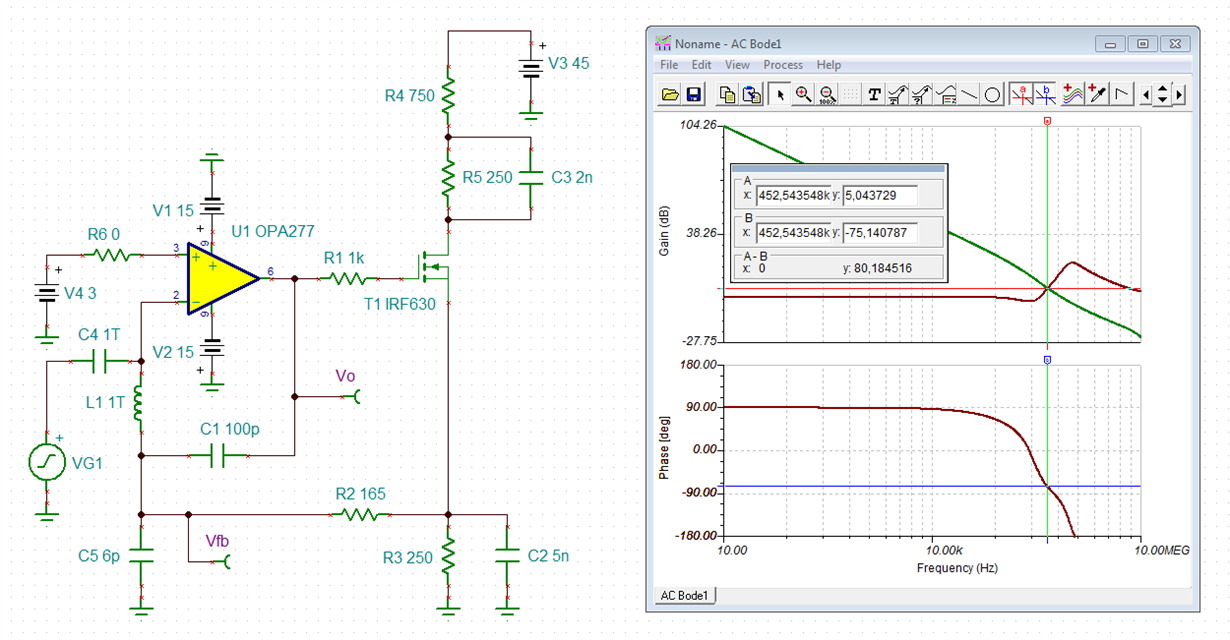

I am using OPA2277s to produce a precision setpoint with an external adjustment. The output noise is okay until either end of the potentiometer is reached and then the noise level jumps up almost .25 volts. Any ideas why?

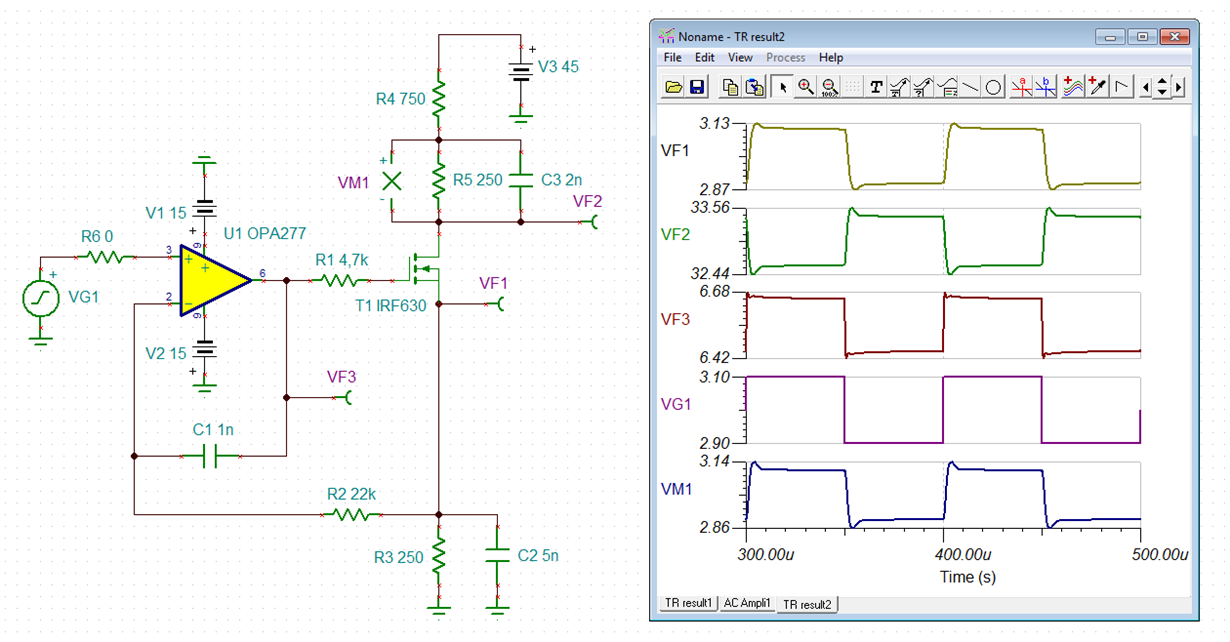

We can mitigate the noise by placing a resistor between the wiper of the potentiometer and the second opa2277.