Hello team,

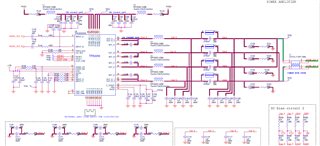

We are using TPA3255 IC for 240W application.

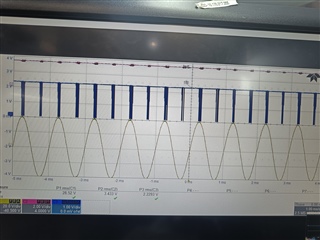

Setup Info - Testing with 4-ohm resistive load.

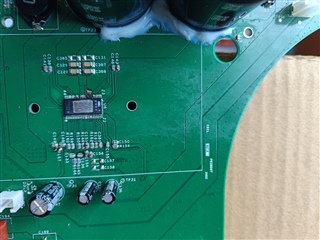

Board 1 - Board Impedance was normal and test was conducted for 2 days. When the DUT was powered on next day, we observed that power pins of IC got damaged, and the pad is also damaged. Image attached for reference. Image attached for reference.

Board 2 - Board Impedance was normal and test was conducted for 2 days. After a gap of 2 days, DUT was turned on, and was behaving normally for 10-15 mins. Later, intermittent output was observed and finally IC was damaged, and smoke was emitted from the same. However, this time only the power pins were damaged, and pad was intact. Image attached for reference.

Thermal Test was done prior to the damage, and the stable temperature with heat sink was ~75-85 deg C.

Also, after the damage, it was observed that output impedance was 0.4, and power supply rail of GVDD, VDD and DVDD was also showing 1.6-ohm impedance.

I kindly request you to help us understand on the possible root cause for the same, as delivery is critical and only 1 working sample is available.