Other Parts Discussed in Thread: TAS2563, TAS2555

Tool/software:

Team,

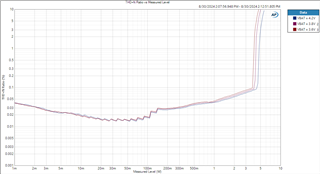

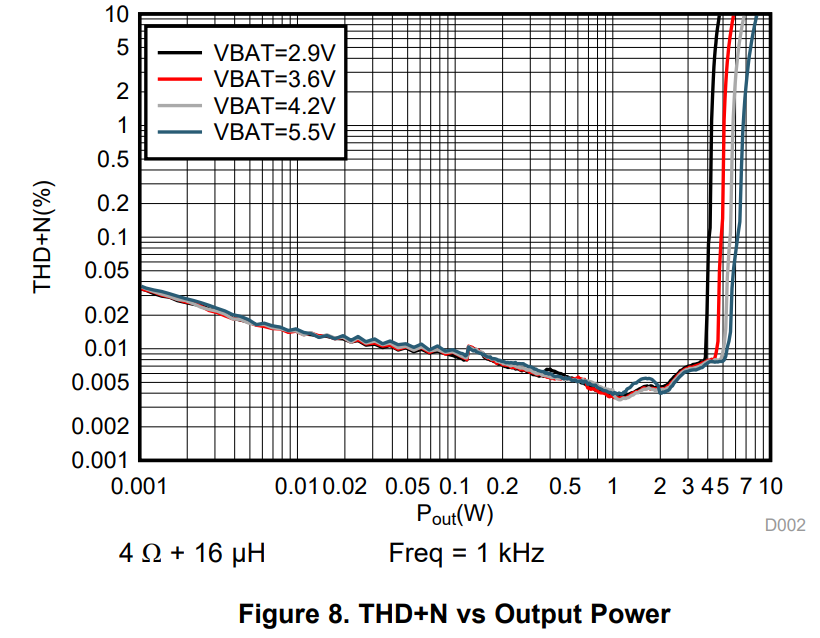

We are using the TAS2559 device in a client's design (AI-enabled Wifi/BT Smart Speaker for consumer electronic product). Here is the datasheet plot to which I am referring:

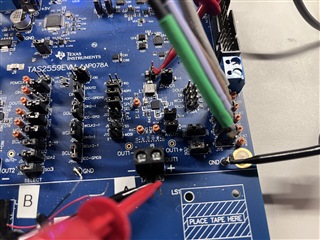

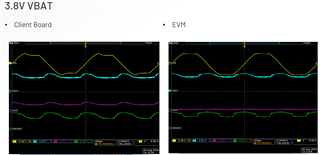

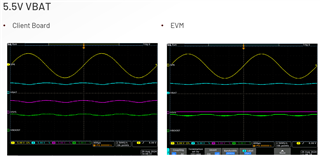

The TAS2559 EVM is not reaching the performance shown above but instead the output becomes clipped as the boost converter output sags at a much lower amplitude. This is true even if we use a DC power supply on VBATT instead of the LiIon battery. We are clipping heavily at only 4.2W (ish). Please see images below.

At customary LiIon battery voltages, we cannot reach rated power with a 4ohm load nor produce the performance plots shown in the datasheet on the EVM. The issue becomes less noticeable if we change the VBAT level to the maximum of 5.5V. You can see this behavior in the attached scope captures. With that in mind, here are our questions:

- Was the EVM used to create the data sheet plots (or was it done on the Characterization/Validation board which may have different construction and components)?

- If the former, why is it that our EVM is unable to meet the spec

- If the latter, can you please provide the schematic of the TAS2559 section as implemented on the Char/Validation board?

- We would like to de-couple the boost converter and the amplifier to test them independently to find out what's happening.

- Can the boost converter be loaded with an external load at the VBOOST net if the amplifier is put in High-Z mode?

- If not, can a load be placed on the VBOOST net while the amplifier is operating without any load (or a really high impedance load)?

- Can we power the Vboost net externally to test whether or not it's the amplifier that is having issues?

- Can we set the TAS2559 to boost to a fixed voltage (say, 6.5VDC with no Class G / Class H modulation) and the amplifier section to operate in pass through mode (i.e. no limiting, no DRC, no Smart Amp, no attenuation or other signal processing)?

- We are unsure if there may be something else happening- either in the data path of the audio amplifier section or in the configuration of the boost converter limits.

- If that isn't the default config coming out of start-up, could you please provide an I2C config file that does this things?

Thermal Characterization Failing.

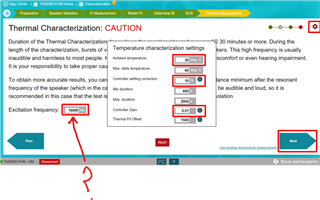

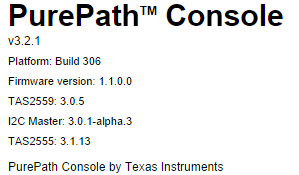

- Another unrelated problem is that the speaker characterization process in PPC3 does not work for our speaker. We've read in various posts and in the SmartAmp Tuning Documentation that the speaker may be too large to get it to heat up enough to register in the PPC3 tool. In the older PPC3 plug in for the TAS2563 there was specific mention of changing the excitation signal from 16kHz to something lower to get the speaker to heat up effectively. However, the latest version of PPC3 seems to have removed that feature. How can we get it back? ... or in some other way change the excitation frequency?

- We read a recommendation on e2e that one could use the onboard speakers of the EVM to, in essence, trick the tool into having some values just to get the tool to progress through the rest of the characterization. I think this isn't a viable solution- afterall, we'd be configuring the SmartAmp algorithms to treat our 3W speaker like it's a 500mW microspeaker... We've also seen in this thread (https://e2e.ti.com/support/audio-group/audio/f/audio-forum/1353576/tas2563ybgevm-dc-learning-board-not-passing-audio-checks) that the tool is flakey and should be restarted/powercycled/unplugged/plugged/etc. We have done that several times to no avail.

- Can we perhaps use a newer device's PPC3 Plug-In, just to extract the thermal characteristics of the speaker and extract them manually?

- Any other ideas?

We are currently gating the client's DV build with these issues, so we'd really appreciate a quick response to help get us unstuck. If a zoom call would be easier, please PM me and I can set that up.