Other Parts Discussed in Thread: CC1352P, PCM1822

Tool/software:

Hi

I read the discussion of the baremetal driver kit for tas2563. ( https://e2e.ti.com/support/audio-group/audio/f/audio-forum/1349736/tas2563-bare-metal-driver/5161027?tisearch=e2e-sitesearch&keymatch=tas2563%20baremetal#5161027 )

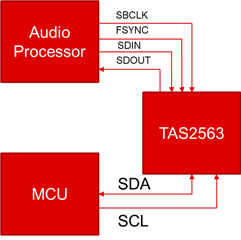

However, our system do not have any drivers or driver-level software. Our systems only have the simplest MCU (about 40pins), CC1352P, echo canceller, PCM1822 (for the analog beep sound from the MCU) and TAS 2563.

(1) Is there any other way for us to configure TAS2563, tune EQ and set the parameters for speaker protection ?

(2) With such a simple architecture, could we write our parameters and information directly to TAS2563 and let TAS2563 memorized?

(3) Continued (2), if we could not do that, what else do we need to add? (e.g. flash? or something?)

Thanks.