Other Parts Discussed in Thread: NE5532

Tool/software:

Hi Raymond,

We are having failures on the production line in China using the new Malaysian parts. We had not experienced any failures using the older Mexican parts with more than a years production.

These are operational failures, not performance failures. The failure rate is a few percent. I have not yet visited the factory, it is in China, to see the issue first hand.

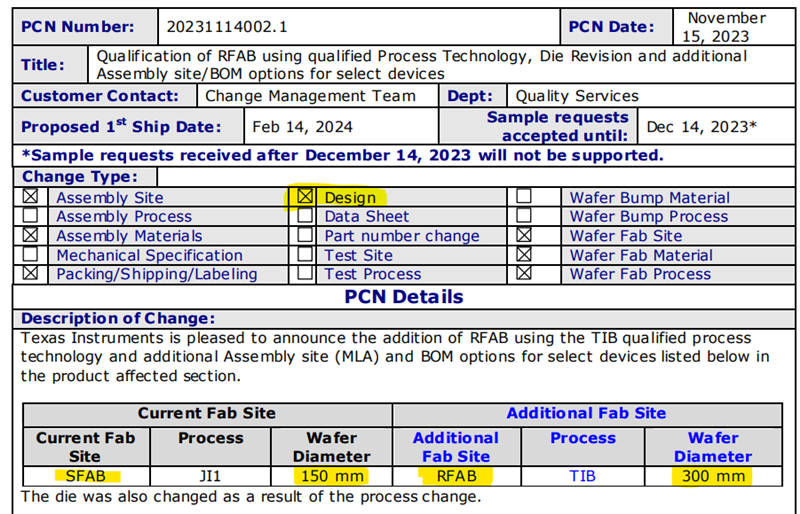

From posts on this forum it appears that you have redesigned the part in a new silicon process to fit a fab running larger wafers. I'm afraid you have changed the device operation in the process.

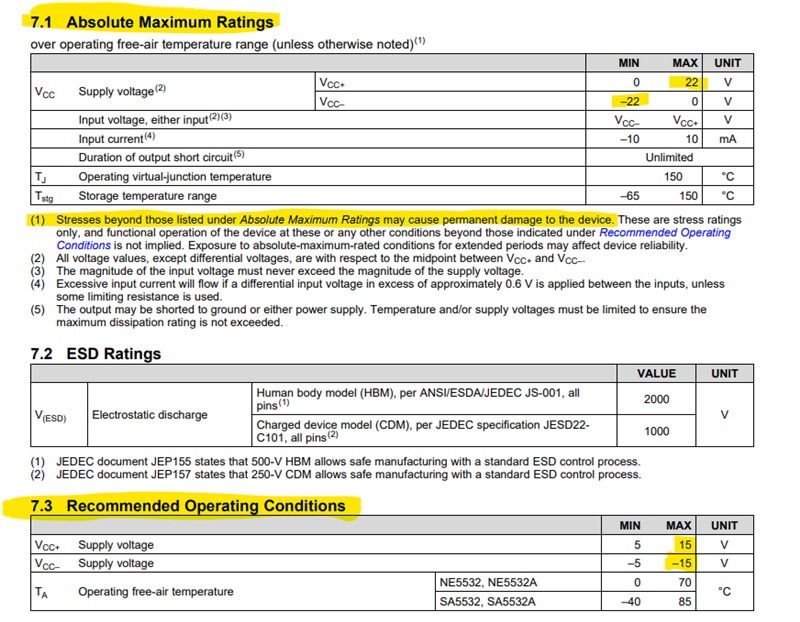

We are running the parts on +/-17V rails, which should not be a problem for the NE5532 since it is rated for +/-22V operation. However, another post implies you aren't supporting anything above +/-15V. The original 5532 from Signetics was designed for the higher voltages and this has been a hallmark of the 5532 ever since.

I cannot share schematics publicly but can send them through private message.

Rich